Tolerance & Surface Finish in CNC Cast Iron Parts: Practical Engineering Guide

2026-01-09 15:57:38 hits:0

Why Tolerance and Surface Finish Matter in CNC Cast Iron Parts

Tolerance and surface finish are critical factors that directly affect the performance, assembly, and service life of cast iron components. In CNC machining, these parameters define how precisely a part is manufactured and how well it interfaces with other components.

For buyers and engineers specifying custom CNC cast iron parts, understanding realistic tolerance ranges and achievable surface quality helps avoid over-engineering, unnecessary cost, and production risks.

Typical CNC Tolerance Ranges for Cast Iron Parts

CNC machining significantly improves dimensional accuracy compared to as-cast components. However, achievable tolerances depend on part size, geometry, and material type.

Common tolerance ranges for CNC machined cast iron parts include:

General dimensions: ±0.1 mm to ±0.2 mm

Critical dimensions: ±0.02 mm to ±0.05 mm

Hole diameters: ±0.02 mm to ±0.1 mm

Flatness / parallelism: within 0.05 mm

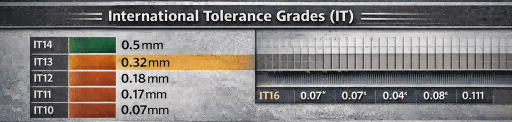

IT Grades and Their Practical Application

International Tolerance (IT) grades are commonly used to define acceptable dimensional variation.

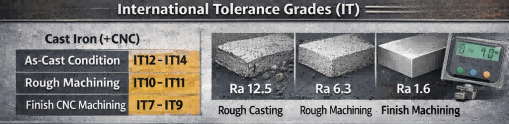

For cast iron parts produced through casting followed by CNC machining:

As-cast condition: IT12–IT14

Rough machining: IT10–IT11

Finish CNC machining: IT7–IT9

Achieving IT6 or tighter is possible in specific cases, but often requires additional setups, rigid fixturing, and increased inspection effort. Engineers should carefully evaluate whether such tight tolerances are functionally necessary.

Surface Finish Standards for CNC Machined Cast Iron

Surface finish is typically expressed as Ra (average roughness), measured in micrometers (µm).

Typical Ra values for cast iron parts include:

As-cast surface: Ra 12.5–25 µm

Rough CNC machining: Ra 3.2–6.3 µm

Finish CNC machining: Ra 0.8–3.2 µm

Gray iron generally achieves smoother finishes more easily due to its graphite flake structure, while ductile iron may require optimized tooling and cutting parameters to reach similar Ra values. Surface finish targets should always align with functional requirements rather than aesthetic expectations.

Realistic Limits of Casting Plus CNC Machining

While CNC machining greatly improves accuracy, it cannot completely eliminate the inherent variability of cast materials.

Key limitations include:

Residual stress from casting: May cause slight distortion during machining

Material structure variation: Especially between gray iron and ductile iron

Part size effects: Larger components are more difficult to hold tight tolerances

Fixturing constraints: Thin walls or complex shapes reduce stability

Balancing Precision, Cost, and Manufacturability

Tighter tolerances and finer surface finishes increase machining time, tooling wear, and inspection requirements. In many applications, specifying unnecessarily tight limits adds cost without improving performance.

Best practices include:

Apply tight tolerances only to functional surfaces

Allow looser tolerances on non-critical features

Define surface finish based on sealing, wear, or assembly needs

Involve manufacturing engineers early in the design phase

A balanced approach leads to cost-effective production while maintaining functional reliability.

Final Thoughts on CNC Cast Iron Tolerance and Surface Finish

Tolerance and surface finish should always be defined based on real functional requirements and manufacturing capabilities. When properly specified, CNC machining delivers reliable precision without excessive cost or risk.

en

en  fra

fra  de

de  ru

ru  ara

ara  gle

gle  it

it  jp

jp  kor

kor  th

th  zh

zh