Best Practices for Designing Custom CNC Cast Iron Components

2026-01-12 17:27:15 hits:0

Why Thoughtful Design is Critical for Cast Iron CNC Parts

The design phase largely determines the success of any CNC machined cast iron component. High-quality materials and advanced machining capabilities cannot fully compensate for poor design decisions.

By carefully planning features, dimensions, and tolerances, engineers ensure parts are not only manufacturable but also cost-effective and reliable. For those sourcing custom CNC cast iron parts, smart design choices prevent unnecessary machining, reduce scrap, and improve consistency across production batches.

Selecting the Appropriate Cast Iron Grade

Material choice should be addressed before finalizing the design. Gray iron and ductile iron have distinct characteristics that influence wall thickness, structural integrity, and the feasibility of complex geometries.

Gray Iron: Ideal for components needing vibration absorption and compressive strength, such as housings or machine bases.

Ductile Iron: Offers higher tensile strength and supports more intricate designs, making it suitable for parts under higher loads or with thinner walls.

Early material selection ensures the design aligns with real-world machining capabilities and avoids over-engineering.

Wall Thickness and Consistency

Maintaining uniform wall thickness is crucial in cast iron part design. Abrupt changes in thickness can lead to internal stresses, casting defects, and dimensional distortions during machining.

Guidelines include:

Keep wall thickness as consistent as possible

Use gradual tapers rather than sharp transitions

Ensure thick and thin sections blend smoothly

Ductile iron allows somewhat thinner walls, but excessively thin sections still pose a machining risk. Consistent walls improve casting integrity and CNC stability.

Fillets, Corners, and Reducing Stress

Sharp internal corners are problematic in cast iron parts—they increase stress concentration and complicate machining.

Designers should:

Replace sharp edges with rounded fillets or radii

Match internal radii to standard cutter sizes

Reduce tool wear and CNC cycle time

Fillets not only improve machining efficiency but also enhance structural strength and casting quality.

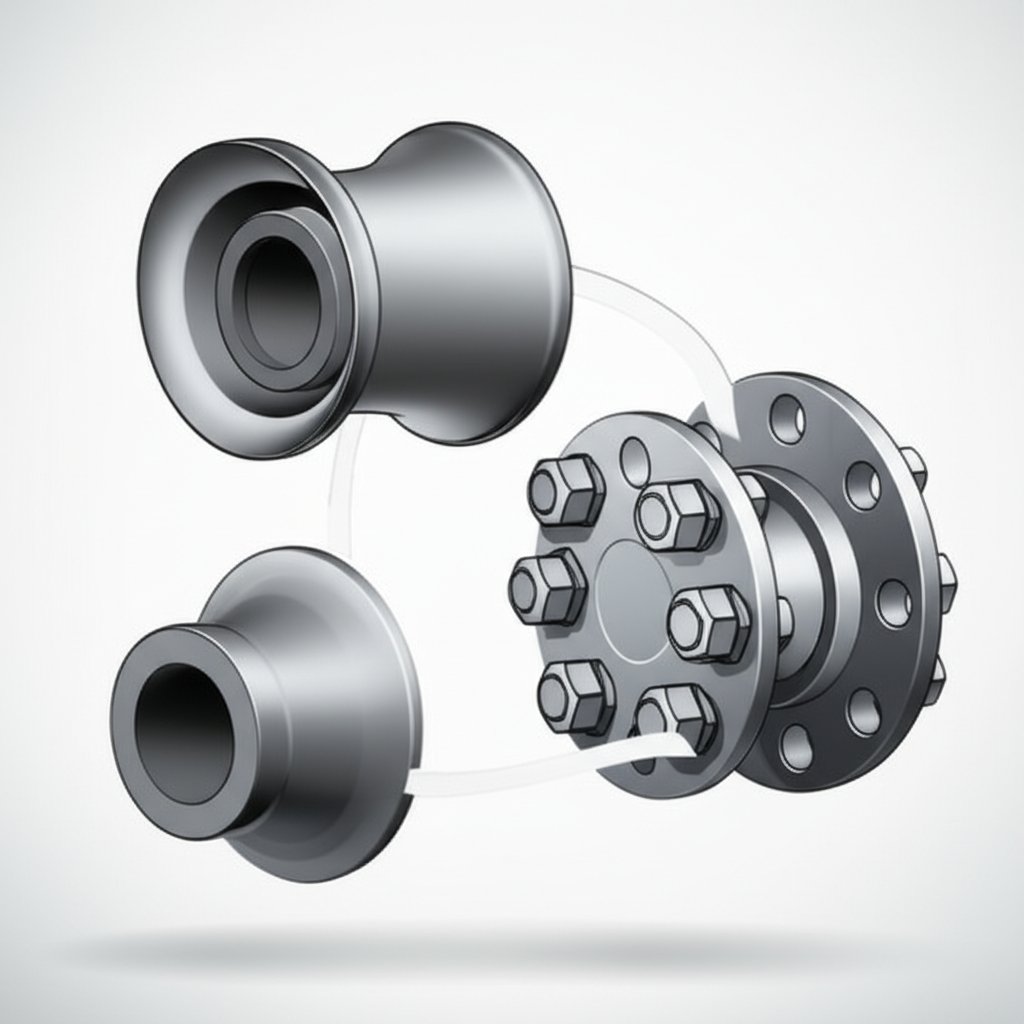

Hole Design Guidelines

Holes often present challenges in CNC machining if not designed thoughtfully.

Best practices:

Avoid excessively deep or narrow holes

Keep depth-to-diameter ratios within practical limits

Ensure holes are perpendicular to main machining surfaces

Threaded holes in ductile iron typically provide better strength. Decide early whether holes will be cast near-net shape or fully machined, as this affects tolerances and production cost. For precision guidance, refer to CNC machining for cast iron components.

Setting Realistic Tolerances

Overly tight tolerances increase machining complexity and cost without necessarily improving function. Critical functional surfaces—like bearing seats, mounting faces, or alignment features—require tighter tolerances, whereas non-functional areas can be more lenient.

Collaborating with manufacturers early ensures tolerances balance performance with manufacturability, particularly for custom CNC cast iron parts.

Surface Finish Considerations

Surface finish impacts sealing, wear, and assembly. While CNC machining can deliver smooth surfaces, specifying ultra-fine roughness everywhere is unnecessary.

Practical approach:

Apply fine Ra values only on functional or contact surfaces

Keep structural surfaces rougher to save machining time

Align finish specifications with real operational needs

This method reduces cost while maintaining functional performance.

Designing for Efficient CNC Machining

Efficient CNC machining starts with design that minimizes complex setups and tooling challenges. Key strategies:

Provide clear reference surfaces for fixturing

Design symmetrical features when possible

Avoid hard-to-reach cavities

These adjustments improve repeatability, shorten lead times, and support production scalability.

Quick Design Checklist

Before finalizing your design, ensure:

Material grade aligns with load and application requirements

Wall thicknesses are uniform with smooth transitions

Sharp corners are replaced with practical fillets

Tolerances are realistic and functional

Machining efficiency has been considered

Addressing these points early leads to reliable, cost-effective parts ready for CNC machining.

en

en  fra

fra  de

de  ru

ru  ara

ara  gle

gle  it

it  jp

jp  kor

kor  th

th  zh

zh