1 What Is a Crankshaft Casting and How Is It Manufactured?

2026-01-13 09:09:11 hits:0

What Is a Crankshaft Casting and How Is It Manufactured?

Quick Answer

A crankshaft casting is a crankshaft produced by pouring molten metal—typically cast iron or ductile iron—into a sand mold. This manufacturing method allows diesel engincomplex crankshaft geometries at a lower cost and is widely used in automotive, diesel, and industrial engines.

What Is a Crankshaft Casting and What Does It Do?

A crankshaft casting is a critical engine component that converts the linear motion of pistons into rotational motion. It transfers combustion energy from the pistons to the drivetrain, enabling engines to deliver power efficiently.

In a cast crankshaft, molten metal is poured into a pre-shaped mold to form the crankshaft’s main journals, crankpins, and counterweights in one integrated structure. This makes casting particularly suitable for producing complex geometries that would be difficult or costly to achieve through other manufacturing methods.

Crankshaft castings are widely used in passenger vehicles, diesel engines, agricultural machinery, power generation equipment, and various industrial applications.

Why Are Many Crankshafts Made from Castings?

Many crankshafts start as castings because casting offers an optimal balance between cost efficiency, design flexibility, and production scalability.

Compared with forging or billet machining, casting allows manufacturers to:

Produce complex shapes with fewer processing steps

Reduce tooling and material costs

Support medium to large production volumes efficiently

For light to medium-duty engines, cast crankshafts provide sufficient strength and fatigue resistance while maintaining competitive pricing, making them a practical choice for OEM and aftermarket applications.

Common Materials Used in Crankshaft Castings

Material selection plays a crucial role in determining the performance, durability, and service life of a crankshaft casting. Common materials include:

Gray Cast Iron – Cost-effective with good vibration damping, commonly used in light-duty engines

Ductile Iron (SG Iron) – Higher tensile strength and fatigue resistance, widely used in automotive and diesel engines

Alloy Cast Iron – Enhanced mechanical properties for higher load and industrial applications

The choice of material depends on engine load, operating conditions, and lifecycle requirements.

【Internal link: Crankshaft material selection guide】

How Is a Crankshaft Casting Manufactured?

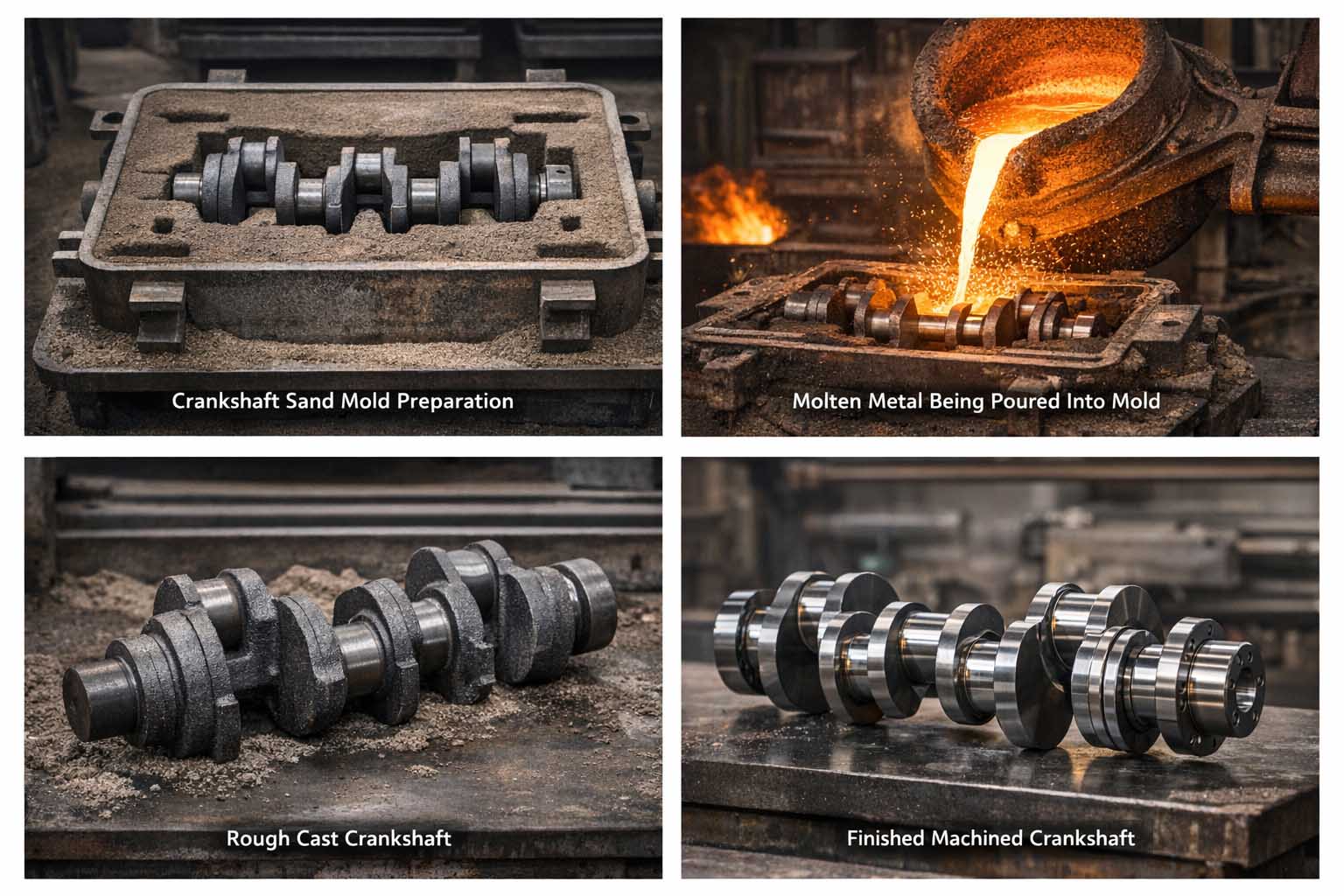

In general, the crankshaft casting process includes mold preparation, molten metal pouring, controlled solidification, cleaning, heat treatment, machining, and final inspection.

Key Manufacturing Steps

1. Design and Mold Preparation

Engineers design the crankshaft using CAD software, defining parameters such as stroke length, journal dimensions, and counterweight configuration. Patterns are then created to form disposable sand molds capable of withstanding high temperatures.

2. Gating System Design

A gating and riser system is designed to ensure smooth metal flow, minimize turbulence, and reduce casting defects such as porosity and shrinkage.

3. Melting and Pouring

Selected metal alloys are melted in controlled furnaces and poured into the sand mold at precise temperatures to ensure proper filling and metallurgical quality.

4. Cooling and Solidification

The molten metal cools and solidifies within the mold. Cooling rates are carefully controlled to avoid internal stresses and cracks.

5. Demolding and Cleaning

After solidification, the sand mold is removed. The rough crankshaft casting is cleaned to remove residual sand and gating materials.

6. Heat Treatment and Machining

Heat treatment processes improve mechanical properties, followed by rough and precision machining to achieve dimensional accuracy and surface finish.

7. Inspection and Quality Control

Dimensional checks and non-destructive testing ensure the crankshaft meets technical and quality requirements.

Crankshaft Casting vs Other Manufacturing Methods

While crankshaft casting is widely used, other manufacturing methods such as forging and billet machining are also available.

Casting is typically chosen for its cost efficiency and design flexibility, whereas forging offers higher fatigue strength for heavy-duty applications. Billet machining is mainly used for high-performance or racing engines where precision outweighs cost considerations.

Crankshaft Castings as the Starting Point for Machining

In many cases, a crankshaft casting serves as the starting point for further machining. Depending on application requirements, it can be supplied as:

A crankshaft blank for customer-side machining

A fully machined crankshaft ready for assembly

Understanding whether to source a blank or finished crankshaft is an important purchasing decision for OEMs and distributors.

Conclusion

A crankshaft casting is a cost-effective and reliable foundation for manufacturing crankshafts used in automotive, diesel, and industrial engines. By combining flexible design, suitable material options, and proven manufacturing processes, casting remains the preferred starting point for many crankshaft applications.

For international buyers and engineers, understanding how crankshaft castings are made—and how material choice and machining affect performance—is essential when evaluating a qualified OEM supplier.

en

en  fra

fra  de

de  ru

ru  ara

ara  gle

gle  it

it  jp

jp  kor

kor  th

th  zh

zh