Custom CNC Cast Iron Parts: Complete Guide for Industrial Applications

2026-01-08 16:09:59 hits:0

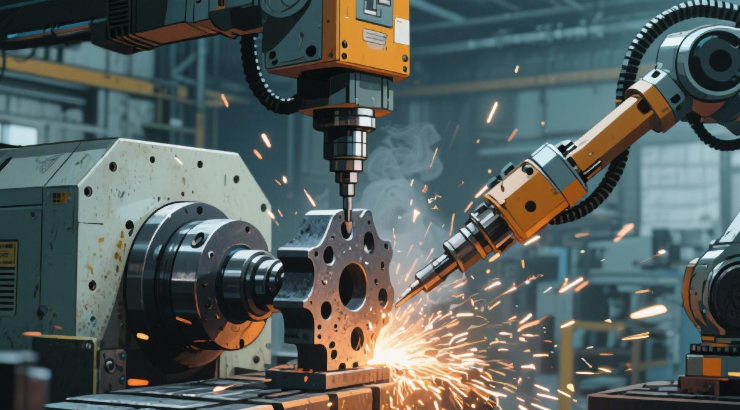

Custom CNC cast iron parts are precision-engineered components manufactured through computer-controlled machining processes using cast iron materials. These parts combine cast iron’s inherent strengths—such as high durability, excellent vibration damping, and wear resistance—with the accuracy of CNC technology. They are critical in industries like automotive, machinery, and construction, where reliability and precision are paramount .

What Are Custom CNC Cast Iron Parts?

Custom CNC cast iron parts involve subtractive manufacturing, where cast iron blanks are shaped using CNC mills, lathes, or drills to meet specific design requirements. Cast iron’s graphite content acts as a natural lubricant, enhancing machinability, while CNC automation ensures tight tolerances and repeatability. These parts are ideal for high-stress applications, including engine blocks, hydraulic components, and industrial machinery frames .

Manufacturing Process of CNC Machined Cast Iron Parts

The production of CNC machined cast iron parts begins with casting molten iron into molds to create rough blanks. These blanks are then machined via CNC equipment, which follows digital designs to cut, drill, and shape the parts. Key steps include:

Casting: Molten iron is poured into molds and solidified using methods like sand casting or lost foam processes .

CNC Machining: Operations like milling, turning, and drilling achieve precise dimensions. CNC machines use carbide tools to handle cast iron’s abrasiveness .

Finishing: Surface treatments such as powder coating, sandblasting, or plating enhance corrosion resistance and aesthetics .

This integrated approach ensures high accuracy and consistency for custom parts.

Material Selection for Cast Iron CNC Parts

Choosing the right type of cast iron is crucial for performance and cost-effectiveness. Common varieties include:

Gray Cast Iron: Offers excellent machinability and vibration damping, suitable for engine blocks and machinery bases .

Ductile Iron: Provides high tensile strength and impact resistance, ideal for gears and automotive components .

White Cast Iron: Known for extreme hardness and wear resistance, used in crusher liners and grinding balls .

Malleable Iron: Balances ductility and strength, often applied in pipe fittings and agricultural machinery .

Selection depends on factors like load requirements, environmental conditions, and machining complexity. Learn more about material comparisons in our guide Gray Iron vs Ductile Iron for Custom CNC Parts.

Design Considerations for CNC Machined Cast Iron Parts

Designing custom cast iron parts requires attention to manufacturability:

Wall Thickness: Maintain minimum thresholds (e.g., 0.3 mm) to prevent cracking during machining .

Radii and Corners: Use generous radii to reduce stress concentration and tool wear.

Tolerances: Specify appropriate tolerances (e.g., ±0.127 mm) to avoid unnecessary costs .

Tool Accessibility: Ensure designs allow easy tool pathing for complex features.

Adhering to these principles minimizes defects and optimizes production efficiency. Explore detailed guidelines in our Design Guide for Custom CNC Cast Iron Parts.

Precision and Surface Finish of CNC Machined Cast Iron

CNC machining achieves tight tolerances (e.g., ±0.01 mm for milling) and fine surface finishes (Ra 3.2–6.3 µm) for cast iron parts. Key factors include:

Tolerance Standards: ISO 8062-3 CT7 for casting, with post-machining refinements .

Surface Treatments: Options like sandblasting (for matte finishes) or polishing (for reflectivity) improve durability and appearance .

Quality Verification: CMM and optical scans validate dimensions, ensuring compliance with specifications .

These aspects are critical for applications in precision industries like aerospace and medical devices. For in-depth insights, see Tolerance & Surface Finish in CNC Cast Iron Parts.

Industry Applications of Custom CNC Cast Iron Parts

Custom CNC cast iron parts are versatile across industries:

Automotive: Engine blocks, brake rotors, and transmission components leverage cast iron’s heat resistance and strength .

Machinery and Tools: Machine bases, gears, and pulleys benefit from vibration damping and wear resistance .

Construction: Pipes, valves, and structural fittings utilize cast iron’s durability in harsh environments .

Energy and Power: Turbines and pump components withstand high pressures and temperatures .

These applications highlight the material’s adaptability. Discover sector-specific cases in Custom Cast Iron Parts by Industry.

Quality Control for CNC Machined Cast Iron Parts

Quality assurance involves rigorous checks at every stage:

Material Inspection: Spectrographic analysis verifies chemical composition .

In-Process Monitoring: Dimensional checks via CMM ensure adherence to tolerances .

Non-Destructive Testing (NDT): Methods like magnetic particle inspection detect subsurface defects .

Certifications: ISO 9001 and IATF 16949 standards guarantee consistency and reliability .

Robust QC protocols ensure parts meet safety and performance standards, such as those for automotive braking systems. Learn more in Quality Control for Custom CNC Cast Iron Parts.

Conclusion

Custom CNC cast iron parts offer a blend of durability, precision, and cost-effectiveness for diverse industrial needs. By understanding material properties, design best practices, and quality measures, businesses can optimize their sourcing strategies. As a leading supplier of precision components, we provide end-to-end solutions for automotive parts, machinery components, and more. Contact us to discuss your project requirements.

en

en  fra

fra  de

de  ru

ru  ara

ara  gle

gle  it

it  jp

jp  kor

kor  th

th  zh

zh