CNC Machining for Cast Iron Components: Precision and Performance Guide

2026-01-08 16:13:30 hits:0

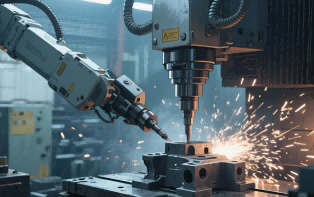

What is CNC Machining for Cast Iron Components?

CNC (Computer Numerical Control) machining is a precise manufacturing process that removes material from cast iron components to achieve the desired dimensions, tolerances, and surface finishes. When combined with custom cast iron manufacturing, CNC machining ensures parts meet strict engineering specifications for industrial applications.

For engineers and procurement managers looking for custom CNC cast iron parts, understanding CNC capabilities is essential to select the right manufacturer and achieve consistent quality.

Capabilities of CNC Machining for Cast Iron

CNC machining can handle a variety of operations on cast iron parts, including:

Milling: Flat surfaces, pockets, and contours

Turning: Cylindrical features and diameters

Drilling and Tapping: Precise holes and threads

Boring and Reaming: High-accuracy holes

Surface Finishing: Achieving Ra values within tight tolerances

CNC machines can process both gray iron and ductile iron components with high precision, making them suitable for machinery housings, pump components, and more.

Precision and Tolerance in CNC Cast Iron Parts

CNC machining offers the ability to achieve tight tolerances. Typical results include:

Linear dimensions: ±0.05 mm to ±0.2 mm depending on part size

Hole diameters: ±0.02 mm to ±0.1 mm

Flatness and parallelism: within 0.05 mm

These tolerances depend on the casting quality and machining complexity. Understanding these limits is crucial for applications that demand precision.

Common Challenges in CNC Machining of Cast Iron

Some challenges include:

Tool Wear: Cast iron is abrasive, requiring high-quality tools.

Vibration and Chatter: Heavy or thin-walled sections can affect surface finish.

Heat Management: Excess heat may cause distortion or micro-cracking.

Material Variability: Gray iron and ductile iron have different machinability.

Experienced manufacturers plan tooling, machine setup, and processes carefully to ensure consistent quality.

Best Practices for High-Quality CNC Cast Iron Components

To achieve optimal results:

Start with a high-quality casting to reduce machining time.

Plan the machining sequence to prioritize critical surfaces.

Use carbide or coated tools for abrasive cast iron materials.

Apply coolant effectively to control temperature and extend tool life.

Perform regular inspection during and after machining.

These practices help deliver reliable components suitable for demanding industrial environments.

Industries Benefiting from CNC Machined Cast Iron Parts

CNC machined cast iron components are widely used in:

Machinery Manufacturing: Housings, gears, and machine bases

Automotive & Transportation: Engine components, brake parts, suspension systems

Water & Pump Systems: Pump casings, valve bodies, and impellers

Energy & Power: Turbine parts and generator housings

Each industry requires precise tolerances and high-quality finishes, making CNC machining an essential step in producing reliable components.

en

en  fra

fra  de

de  ru

ru  ara

ara  gle

gle  it

it  jp

jp  kor

kor  th

th  zh

zh