Gray Iron vs Ductile Iron for Custom CNC Parts: Which Material Should You Choose?

2026-01-09 15:28:27 hits:0

Understanding Gray Iron and Ductile Iron in Custom CNC Parts

Gray iron and ductile iron are the two most commonly used materials for custom cast iron components. While both are suitable for CNC machining, their mechanical properties, machinability, and application suitability differ significantly.

When selecting materials for custom CNC cast iron parts, understanding these differences helps engineers and buyers balance performance, cost, and manufacturability.

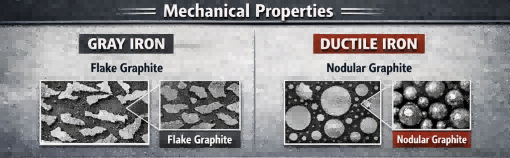

Mechanical Properties Comparison

The most fundamental difference between gray iron and ductile iron lies in their graphite structure, which directly affects strength and toughness.

Gray Iron

Graphite appears in flake form

Excellent vibration damping

Lower tensile strength

Brittle under impact loads

Ductile Iron

Graphite appears in spherical (nodular) form

Higher tensile and yield strength

Superior impact resistance

Better fatigue performance

For load-bearing or safety-critical components, ductile iron is often preferred due to its mechanical reliability.

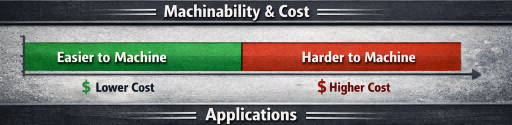

Machinability and CNC Processing Characteristics

Both materials are widely used in CNC machining, but their behavior during cutting differs.

Gray iron is known for:

Excellent machinability

Lower cutting forces

Natural lubrication from graphite flakes

Reduced tool wear

Ductile iron, while still machinable, typically:

Requires more robust tooling

Generates higher cutting forces

Produces longer chips

Benefits from optimized CNC parameters

If your project involves extensive finishing operations, understanding CNC machining for cast iron components can help determine which material offers better efficiency and tool life.

Strength, Durability, and Application Suitability

Material selection should be driven by the functional requirements of the part.

Gray iron is commonly used for:

Machine bases

Gear housings

Pump casings

Components requiring vibration absorption

Ductile iron is better suited for:

Pressure-containing parts

Structural components

Automotive and transportation parts

Applications requiring impact resistance

In many industrial projects, ductile iron provides a safety margin that gray iron cannot offer under dynamic loads.

Cost Considerations: Gray Iron vs Ductile Iron

Cost is often a deciding factor in material selection.

Gray iron generally:

Has lower raw material cost

Requires less complex metallurgy

Offers faster CNC machining

Ductile iron:

Has higher material and processing cost

Requires magnesium treatment during casting

May increase CNC machining time

However, for parts where failure risk is high, the higher initial cost of ductile iron may reduce long-term operational and maintenance costs.

Choosing the Right Material for Custom CNC Applications

Selecting between gray iron and ductile iron depends on several factors:

Load and stress conditions

Required mechanical strength

CNC machining complexity

Budget constraints

Service environment

Engineers often evaluate these factors early in the design phase to avoid costly redesigns or performance issues later in production.

Final Recommendation for Custom CNC Cast Iron Parts

There is no universal “better” material—only the right choice for a specific application. Gray iron offers excellent machinability and cost efficiency for stable, low-stress components, while ductile iron delivers superior strength and durability for demanding environments.

For a complete overview of material selection, machining, and production workflows, visit our Custom CNC Cast Iron Parts pillar page, where all related topics are explained in detail.

Related Resources

To further explore this topic, you may also find these guides helpful:

CNC Machining for Cast Iron Components – machining capabilities and tolerances

Tolerance & Surface Finish in CNC Cast Iron Parts – understanding precision limits

Design Guidelines for Custom CNC Cast Iron Parts – best practices for manufacturable designs

en

en  fra

fra  de

de  ru

ru  ara

ara  gle

gle  it

it  jp

jp  kor

kor  th

th  zh

zh