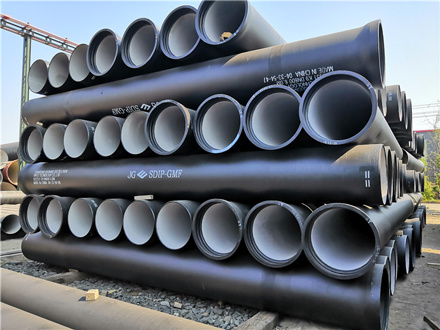

Global Supply | Ductile Iron Pipes DN80–DN2600 | Water & Sewer Solutions

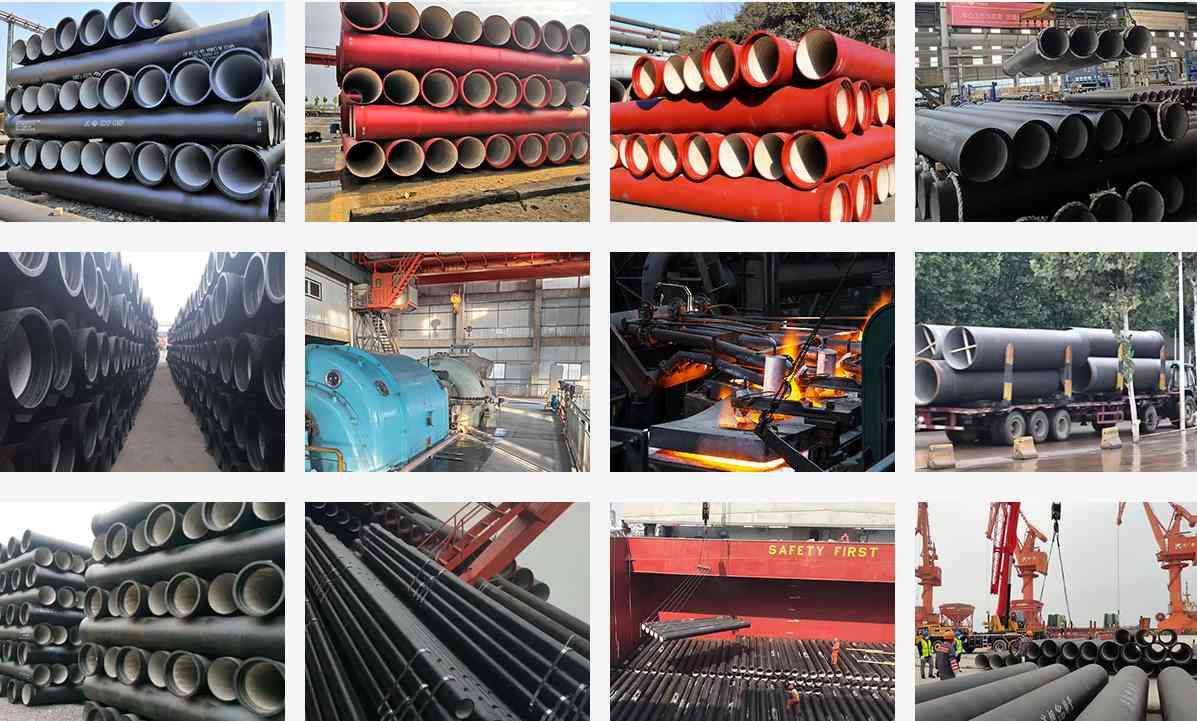

We are a professional international pipeline solutions provider. Our products are sourced from top industry manufacturers with 60+ years of casting experience, specifically engineered to withstand high corrosion, ground subsidence, and other complex environments.

1. International Standard Certification: Strictly comply with ISO 2531 / EN 545.

2. Superior Anti-Corrosion & Seismic Resistance: Zinc coating ≥130g/m², high joint flexibility.

3. Stable & Flexible Supply Chain: Large-scale stock available, capable of matching budget requirements.

Get Your Customized Project Quote (FOB/CIF) Now!

Introduction

▉Our Strength & Quality Assurance

Certified Excellence, Proven Strength

One of the few in the industry with multiple system certifications, recognized by BV (France), SGS (Switzerland), TÜV (Germany), demonstrating global trust in our quality and service.

Six Decades of Heritage: Our manufacturing partners were among the first in China to produce according to the ISO 2531 international standard, boasting over 60 years of casting history.

World-Class Capacity: The manufacturer is one of the largest single-entity DIP producers globally, with annual sales approaching ¥5 billion, ensuring stable delivery for orders of any scale.

Authoritative Certification: The quality system is ISO 9001 certified, with coating inspections strictly adhering to standards like ISO 8179.

▉Core Technical Specifications & Performance

▍Basic Specifications

Item | Specification |

|---|---|

| Standard | Comply with ISO 2531, EN 545, GB/T 13295, ISO 8179, ISO 16132 and other major international & Chinese standards. |

| Diameter Range | DN80 – DN2600 |

| Wall Thickness | K Class, C Class |

| Length | 6m (standard) / Custom available |

| Internal Lining | Cement Mortar, Sulfate-Resisting Cement, Epoxy, Polyurethane, Ceramic Epoxy, Polyethylene |

| External Coatings | Zinc Coating with Asphalt Topcoat, Polyethylene Sleeve, Polyurethane Coating, Aluminum Paint |

| Joint Types | T-Type, GMT-Type, K-Type, TF Restrained Joint, Tiegu Restrained Joint |

| Installation Methods | Trench Installation, Pipe Jacking, Sunk Pipe Method, Horizontal Directional Drilling |

| Product Series | Pipes, Fittings, Accessories |

| Services | Pre-Sales & After-Sales Services |

| Applications | Water supply, sewage, irrigation, reclaimed water, heating |

▍Superior Performance

Our products not only meet but exceed standards, with superior mechanical performance that ensures long-term durability in severe environments.

The following data illustrates the excellent mechanical performance of our ductile iron pipes, exceeding international standards.

Performance Metric | Data |

| Tensile Strength | ≥ 420 MPa |

| Flexural Strength | ≥ 590 MPa |

| Elongation | DN80–1000 ≥ 10% / DN1100–1600 ≥ 7% |

| Modulus of Elasticity | ≈ 17 × 10⁴ N/mm² |

| Thermal Conductivity | 42 |

▍Joints & Anti-Corrosion System

Joint Solutions: We offer the T-Type Flexible Joint (for standard supply, fast installation) and Self-Anchored Joints (for steep slopes, ground subsidence, eliminating concrete thrust blocks).

Our ductile iron pipes are equipped with long-lasting corrosion protection systems designed to meet the requirements of different water qualities and soil environments.

The external coating strictly follows ISO 8179, with a zinc spraying rate ≥ 130 g/m², ensuring excellent resistance against soil corrosion.

For internal linings, we offer multiple customized options such as ordinary Portland cement, sulphate-resistant cement, and epoxy resin coatings, providing reliable protection for various conveyed media.

The table below serves as a reference guide for selecting suitable internal and external corrosion protection systems according to different project conditions.

🧱 Internal & External Corrosion Protection Options

Water Quality / Soil Environment | Recommended Internal Lining | Recommended External Coating |

|---|---|---|

| Raw Water / Drinking Water | - Ordinary Portland Cement Lining - Sulphate-Resistant Cement Lining - PE Lining | - Zinc + Finishing Coating |

| Potable Water / Soft Water | - Cement Lining + Epoxy Sealing Layer - Epoxy Ceramic Lining - Polyurethane Lining | - Zinc + Finishing Coating |

| Municipal Sewage | - High-Alumina Cement Lining - Epoxy Ceramic Lining - Polyurethane Lining | - Standard Coating + Polyethylene Sleeve |

| Industrial Wastewater | - Polyurethane Lining | - Polyurethane Coating |

| Normal Corrosive Soil | (Based on conveyed water type) | - Zinc + Finishing Coating |

| Moderately Corrosive Soil | (Based on conveyed water type) | - Standard Coating + Polyethylene Sleeve |

| Strongly Corrosive Soil | (Based on conveyed water type) | - Polyurethane Coating |

▉Quality & Flexibility

All pipes are manufactured under strict quality control systems. Each pipe undergoes hydrostatic pressure testing, coating thickness inspection, and mechanical performance testing before delivery.

We support standard and customized production, enabling fast response to various project requirements.

▉Your Strategic Advantage: Flexible Global Supply

※Quality Priority, Supply Flexibility

Supply Chain Advantage: We prioritize top-quality products while using our strong supplier network to provide cost-effective alternatives that meet international standards, addressing strict budget constraints and non-standard requirements

※Professional Foreign Trade Service

We offer FOB/CIF pricing and assist with shipping, customs clearance, and inspection procedures to ensure reliable and timely delivery to your port.

▉Final Call to Action

Whether you're planning a municipal water project, an irrigation system, or a district heating network, our ductile iron pipes provide a reliable and cost-effective solution.

Contact us today to get technical support and the best quotation for your project.

Anhui Tiegu Information Technology Co., Ltd

Anhui Tiegu Information Technology Co., Ltd

Tel.:+86-15256135588

Tel.:+86-15256135588

E-mail:zbw@tiegu.net

E-mail:zbw@tiegu.net

Add.:19th Floor, Building 1, Jinnuode Technology Incubator, No. 1686 Xiyou Road, High tech Zone, Hefei City, Anhui Province, China

Add.:19th Floor, Building 1, Jinnuode Technology Incubator, No. 1686 Xiyou Road, High tech Zone, Hefei City, Anhui Province, China

👉 Click here to get a free quotation

Frequently Asked Questions

Do you have an advantage in price?

We have a great price advantage and have saved purchasing costs for 300 + municipal projects, be sure to get a quote from Tiegu before you purchase, as we believe it will be beneficial to reduce your costs.

Do you provide samples?

Yes, we offer test samples. If you are interested in our products and would like to evaluate them before purchasing in bulk, you can request a sample. Please feel free to contact our team if you need a sample.

What is the minimum order quantity for your products?

Generally we have sufficient stock of ductile cast pipes and fittings in regular diameters and pressures, please forward an RFQ to our sales team for more details.

What countries do you export to?

We have exported our products to USA, Canada, Brazil, Chile, Colombia, Russia, Ukraine, Thailand, Myanmar, Vietnam, India, Kenya, Ghana, Somalia, Ethiopia and other African countries. We have rich export experience and are familiar with different market demands, which can help our customers avoid a lot of troubles.

How do you ensure the quality of your products?

We have established a comprehensive quality management system to ensure that we provide high quality materials to our valuable customers. We accept third party factory inspection. Please contact the sales team for QCP details.

What product information do I need to provide?

You will need to provide the grade, width, thickness, coating and tonnage you need to purchase.

What is the delivery time for your products?

Usually 3-15 days. Delivery times will vary depending on the specific requirements of the order and our production schedule.

Photos

en

en  fra

fra  de

de  ru

ru  ara

ara  gle

gle  it

it  jp

jp  kor

kor  th

th  zh

zh