Composite Manhole Cover Series Product Introduction

Tiegu composite manhole cover series includes round, square, flower pot types, with features of anti-theft, pressure resistance, durability and stable quality.Offering composite water meter boxes, drainage ditches and customized solutions, direct supply from manufacturer ensures quality and after-sales service.

Introduction

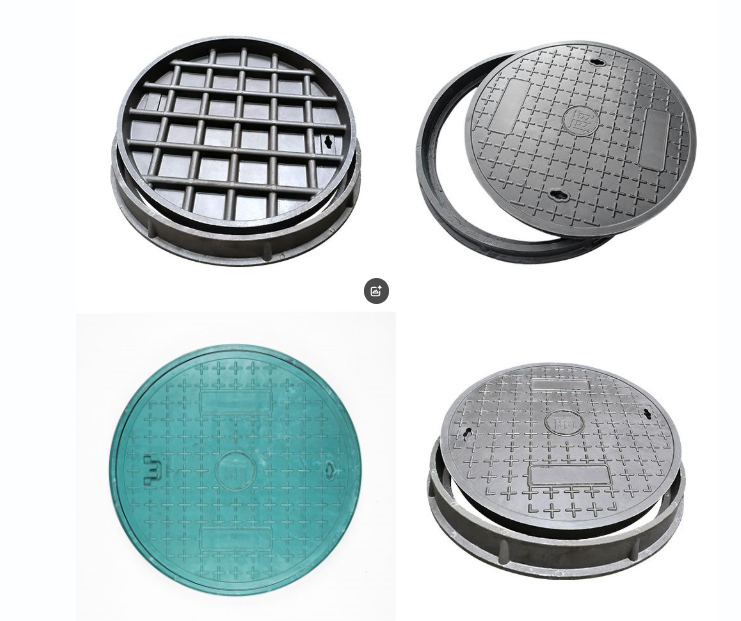

Composite Manhole Cover Series

Catalogue

Product Performance Features

(I) Anti-Theft Feature

Manufactured using unsaturated polyester resin and glass fiber short strands as raw materials, formed in a single molding process. As the

molding process involves an irreversible chemical reaction, the product has no recycling value, fundamentally preventing theft at the material source and reducing the risk of loss.

(II) Pressure Resistance & Durability

The product boasts high density and incorporates internal reinforcing ribs, significantly enhancing its load-bearing capacity. It also exhibits excellent freeze resistance, aging resistance, and acid/alkali resistance, adapting to diverse and complex environments. This ensures long-term stable performance, reducing frequent replacement costs.

(III) Stable Quality Advantage

Utilizes fully automated, mechanical production processes. Relying on hydraulic presses, the product is formed in a single press under high temperature through multiple stages. Compared to manual operations, this greatly minimizes human factor interference, ensuring consistent specifications, performance, and stable, controllable quality across every batch.

Tiegu Composite Manhole Cover Series includes: Composite Round Manhole Covers, Composite Square Manhole Covers, Composite Utility & High-Speed Covers, Composite Meter Boxes, Composite Drainage Channels, Composite Flower Pot Manholes.

▲Contact us immediately to get the product catalog.

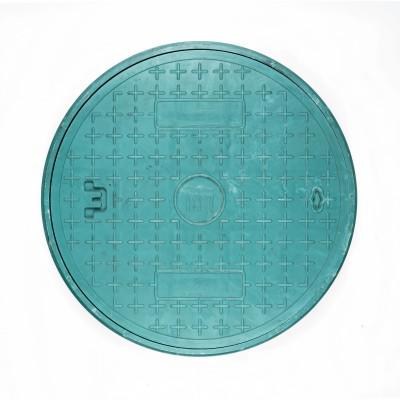

Composite Round Manhole Cover

The composite cover utilizes a pot-bottom structure, increasing the load-bearing area dozens of times compared to plate-rib designs. The entire structural layer is formed from continuous high-strength composite materials, ensuring even stress distribution. This design results in superior load-bearing capacity.

Composite covers feature high hardness. The addition of UV absorbers and other anti-aging agents doubles wear resistance and service life. Furthermore, reinforcing materials prevent the delamination and spalling issues common in other composite products. These features meet the load-bearing requirements of manhole covers while guaranteeing long-term, stable, and reliable intrinsic material quality.

Composite Round Manhole Cover Specifications & Models

| Size (MM) | Load Class | Size (MM) | Load Class |

|---|---|---|---|

| φ200 | A15 - C250 | φ700 | B125 - D400 |

| φ300 | A15 - C250 | φ750 | B125 - D400 |

| φ360 | A15 - C250 | φ760 | B125 - D400 |

| φ400 | A15 - C250 | φ800 | B125 - D400 |

| φ500 | A15 - D400 | φ900 | B125 - D400 |

| φ600 | A15 - D400 | φ1000 | B125 - D400 |

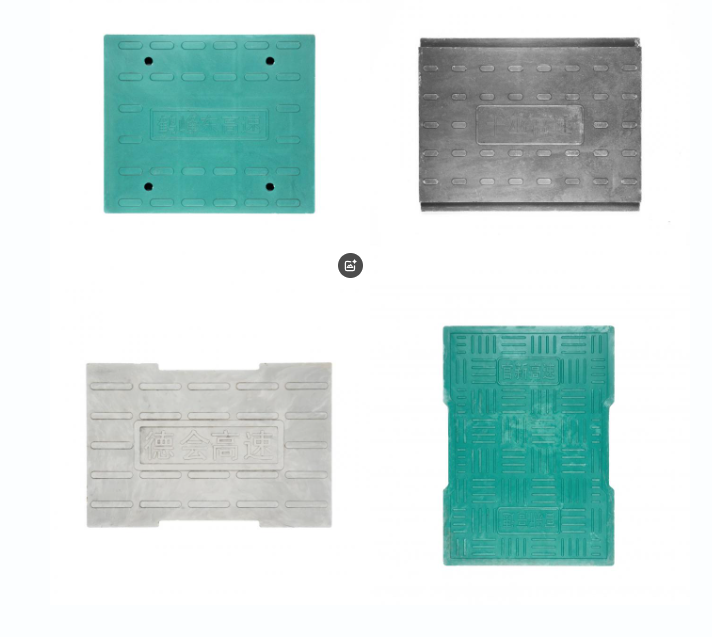

Composite Square Manhole Cover

Composite Square Manhole Cover Specifications & Models

| Size (MM) | Load Class | Size (MM) | Load Class |

|---|---|---|---|

| 200*530 | A15 - B125 | 580*680 | B125 - D400 |

| 220*530 | A15 - B125 | 600*600 | B125 - D400 |

| 250*450 | A15 - B125 | 600*800 | B125 - D400 |

| 300*300 | A15 - D400 | 700*700 | B125 - D400 |

| 300*450 | A15 - D400 | 700*750 | B125 - D400 |

| 300*500 | A15 - D400 | 700*1050 | B125 - D400 |

| 400*400 | B125 - D400 | 750*1000 | B125 - D400 |

| 400*500 | B125 - D400 | 800*1000 | B125 - D400 |

| 400*600 | B125 - D400 | 860*470 | B125 - D400 |

| 450*750 | B125 - D400 | 860*940 | B125 - D400 |

| 450*840 | B125 - D400 | 900*840 | B125 - D400 |

| 500*500 | B125 - D400 | 1000*1000 | B125 - D400 |

| 500*1000 | B125 - D400 | 1040*1060 | B125 - D400 |

| 510*680 | B125 - D400 | 1040*1590 | B125 - D400 |

Composite Utility & High-Speed Covers

Composite Utility & High-Speed Covers Specifications & Models

| Size (MM) | Size (MM) | Size (MM) | Size (MM) | Size (MM) | Size (MM) | Size (MM) | Size (MM) |

|---|---|---|---|---|---|---|---|

| 470*860 | 490*730 | 495*690 | 500*500 | 500*580 | 500*600 | 500*700 | 500*800 |

| 500*900 | 500*1000 | 500*1100 | 500*1200 | 500*1300 | 500*1400 | 500*1500 | 500*1600 |

| 500*1700 | 500*1800 | 500*2000 | 500*2100 | 500*2600 | 630*1200 | 800*1200 | 1000*1000 |

Composite Meter Box

Meter boxes are formed in a single high-pressure molding process using SMC (Sheet Molding Compound), resulting in an aesthetically pleasing appearance with a smooth, flat surface, uniform color, and resistance to scratches.

Composite Meter Box Specifications & Models

Size (MM) Type Size (MM) Type Size (MM) Type 200*530*130 Whole Box 300*430*200 Whole Box 530*960*40 Whole Box 220*530*30 Whole Box 300*500*200 Whole Box 630*300*40 Whole Box 250*450*120 Whole Box 530*320*40 Whole Box 630*600*40 Modular 250*500*30 Whole Box 530*320*120 Whole Box 1000*500*50 Whole Box 280*450*350 Whole Box 530*640*40 Whole Box 1000*1000*50 Modular

Composite Drainage Channel

Composite Drainage Channel Specifications & Models

| Size (MM) | Size (MM) |

|---|---|

| 200*200*1000*30A | 250*250*1000*30B |

| 200*200*1000*30B | 300*300*1000*30A |

| 250*250*1000*30A | 300*300*1000*30B |

Composite Flower Pot Manhole

A new type of flower pot manhole cover, an alternative to traditional covers,

manufactured using new processes, new materials, and innovative techniques: the Composite Resin Grass Planter Manhole Cover.

Also known as Grass Manhole Cover, Recessed Planter Well, etc.

Composite Flower Pot Manhole Specifications & Models

| Size (MM) | Load Class | Size (MM) | Load Class |

|---|---|---|---|

| φ400 | A15 - B125 | 400*400 | A15 - B125 |

| φ500 | A15 - B125 | 500*500 | A15 - B125 |

| φ600 | A15 - B125 | 500*1000 | A15 - B125 |

| φ700 | A15 - B125 | 600*600 | A15 - B125 |

| φ800 | A15 - B125 | 700*700 | A15 - B125 |

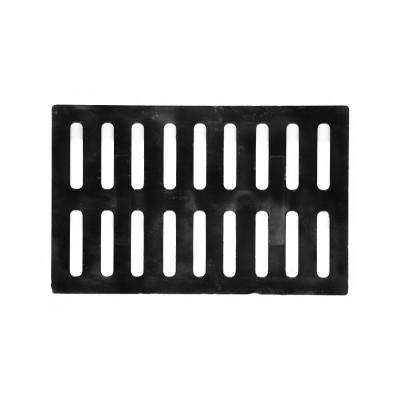

Composite Single Grate

The Composite Single Grate is made of high-strength composite materials, designed for various locations requiring high load-bearing capacity.

The Composite Single Grate is made of high-strength composite materials, designed for various locations requiring high load-bearing capacity.

Its unique corrosion resistance and compressive strength make it widely applicable in urban construction, road traffic, and stormwater drainage systems.

Particularly suitable for municipal projects, industrial parks, shopping malls, residential areas, and other road and drainage systems.

Product size :can be customized as needed (250-500mm * 500-1500mm), suitable for different load requirements (B125-D400), widely meeting the bearing demands of various engineering projects.

Composite Set Grate

The Composite Set Grate is made of high-strength composite materials, specifically designed for municipal drainage systems.

Widely used in urban roads, industrial parks, commercial areas, and other stormwater drainage systems.

As a high-performance drainage component, the Composite Set Grate combines the lightweight and strength advantages of composites and features a structure that ensures tight integration with drainage wells, guaranteeing efficient use.

Product size :

Weight: Customizable as needed, Size: 300*500 - 800*1000

Application Fields

Our products are suitable for the following industries and scenarios:

Municipal Roads

Residential Communities

Telecommunication Projects

Water Supply Systems

Gas Distribution

Featuring rational design, lightweight, colorable, non-recyclable (anti-theft), high load-bearing capacity, and stable product quality, they meet diverse usage needs. Ideal for municipal roads, communities, industrial facilities, and other application scenarios.

▲Get Municipal Manhole Cover Solutions

▲Get Municipal Manhole Cover Solutions

Product Manufacturing Process

Raw Material Preparation: Complete the production of BMC dough or SMC sheets, preparing the base materials for cover production.

Skeleton Reinforcement: Precisely weld mesh steel reinforcement skeletons according to product mold design. Structural strengthening enhances load-bearing performance, forming a solid mechanical foundation.

Material-Skeleton Integration: Place BMC dough / SMC sheets into the hydraulic press, integrating them with the steel skeleton to achieve composite material-structure synergy under load.

Mold Pre-treatment: Install the assembled mold onto the vertical four-column hydraulic press. Complete electrical heating to reach the fixed temperature required by the process.

Molding Process: Precisely weigh the raw material according to the product's specified weight. First, evenly distribute the mixed material in the mold cavity. Place the steel skeleton inside, then add the remaining material to the feed chamber. Close the mold and apply pressure. Strictly control pressure adequacy, distribution uniformity, and time stability throughout the process to ensure key performance metrics like load-bearing capacity and density.

Post-processing: Remove the molded cover. Trim flash edges, cool for setting. After passing inspection, the finished product is shipped to market.

About Us

Tiegu provides municipal infrastructure products, including manhole covers, resin covers, composite covers, composite grates, ductile iron covers, cast iron drain grates, cable trench covers, FRP covers, drainage channel covers, planter well covers, meter boxes, and other supporting products for municipal construction. Product weights range from 0.5KG to 200KG. Material grades include high-strength ductile iron such as QT400-15, QT450-10, QT500-7, QT600-3. Our product range covers the vast majority of manhole cover sizes and types on the market.

The company primarily uses green sand molding methods, equipped with multiple fully automated vertically-parted flaskless shoot-squeeze molding lines, core-making equipment, medium-frequency induction furnaces, sand processing lines, and casting cleaning equipment. We possess advanced testing equipment including rapid front analysis instruments, German SPECTRO spectrometers, metallographic microscopes, and universal testing machines.

Contact Us

WhatsApp: 15256135588 (First 10 inquiries receive extra gifts)

E-mail:zbw@tiegu.net

Apply for Pilot: Click the link to get a customized solution (First batch of customers enjoy 20% discount)

The Tiegu Composite Manhole Cover Series, with its mature technology and stable performance, contributes to the protection of the "underground pulse" of the city and is an excellent choice for manhole cover applications in various industries.

Photos

en

en  fra

fra  de

de  ru

ru  ara

ara  gle

gle  it

it  jp

jp  kor

kor  th

th  zh

zh