Ductile Iron Pipes: Comprehensive Solutions for Fluid Transportation From China Supplier

Tiegu, a leading comprehensive enterprise specializing in fluid transportation solutions. We combine self-manufacturing and national agency models to offer a wide range of high-quality ductile iron pipes from DN80 to DN3000, suitable for various applications including municipal water supply & drainage, industrial fluid transportation, agricultural water conservancy, and fire protection systems. Our pipes boast exceptional mechanical performance with high strength, superior toughness, and excellent corrosion resistance, featuring multi-layer anti-corrosion coatings and leak-proof sealing designs. With a long lifespan of over 50 years and 100% recyclability, our products are compliant with international standards such as ISO 2531, EN 545, and AWWA C151, and certified by DNV GL, SGS, and FM. We provide one-stop procurement, full-life-cycle services, and rapid response to meet your diverse needs. Choose Tiegu for reliable and efficient fluid transportation solutions!

Introduction

I. Corporate Positioning and Core Advantages

As a comprehensive enterprise integrating self-manufacturing and national agency, we adopt a dual-drive model to deliver leading fluid transportation solutions. Our in-house foundry uses centrifugal casting technology to produce 500,000 tons of ductile iron pipes annually, covering DN80-DN3000 diameters—among which DN3000 ultra-large diameter pipes increase water transmission capacity by 20x compared to DN1000 while reducing material consumption by 19%. We also represent over 10 renowned domestic pipe brands, integrating resources to serve municipal, industrial, agricultural, and fire protection sectors with one-stop procurement and full-life-cycle services.

II. Product Technical Features

1. Exceptional Mechanical Performance

High Strength: Tensile strength ≥420MPa, yield strength ≥300MPa, capable of withstanding 250bar burst pressure—far exceeding ordinary cast iron pipes.

Superior Toughness: Elongation rate ≥10%, excellent impact resistance, passing 8-grade seismic tests, suitable for complex environments with geological subsidence or earthquakes.

High External Load Resistance: Semi-rigid structure design withstands vehicle rolling load and soil extrusion, ideal for heavy-load areas.

2. Leading Corrosion Resistance

Natural Material Resistance: Spherical graphite minimizes matrix disruption,offering better acid-alkali resistance than gray cast iron, usable in sewage environments with pH4.5-12 for long-term service.

Multi-layer Anti-corrosion Coatings:

Internal Lining: Cement mortar, epoxy resin, or epoxy ceramic lining (resistant to strong acids/alkalis), reducing friction coefficient by 15% and improving water transmission efficiency by 20%.

External Coating: Zinc layer + asphalt paint composite coating (1000-hour salt spray test), or customized FBE/PU coatings for coastal high-salt environments.

3. Leak-proof Sealing and Easy Installation

Flexible Joint Design: T-type socket (rubber ring seal) or K-type mechanical joint allows ±3° angular deflection and axial displacement, ensuring seismic resistance and zero leakage after installation.

Rapid Construction: No welding or special tools needed, single-person operation, construction efficiency 30% higher than steel pipes.

4. Environmental Friendliness and Economy

100% Recyclable: Ductile iron is fully recyclable, compliant with green building standards.

Long Lifespan & Low Maintenance: Designed for over 50 years of service, 20% lower comprehensive cost than PE pipes. Used in Singapore Changi Water Treatment Plant with a 20-year leak-free record.

III. Technical Parameters and Certifications

Diameter Range: DN80-DN3000 (3"-120"), covering municipal main pipes to community branch pipes; DN3000 ultra-large diameter pipes fill domestic market gaps.

Pressure Rating: K7-K9 grades, working pressure ≤40bar, test pressure ≥1.5x working pressure.

Standards: Compliant with ISO 2531, EN 545, AWWA C151; certified by DNV GL, SGS, and other international bodies.

Joint Types: T-type, K-type, self-anchoring, flanged—adaptable to various installation requirements.

IV. Full-scenario Applications and Benchmark Cases

1. Municipal Water Supply & Drainage

Wastewater Network Renovation in a Second-tier City: Combined self-manufactured K9-grade pipes with agency-brand epoxy ceramic-lined pipes, reducing comprehensive costs by 18% and construction time by 25%.

Water Main Upgrading in Wendeng District: Replaced 30-year-old DN1000 cement pipes with ductile iron pipes, increasing water supply capacity by 30% and reducing annual leakage rate to <0.5%.

2. Industrial Fluid Transportation

Corrosive Wastewater in a Chemical Park: Agency-brand epoxy ceramic-lined pipes (resistant to strong acids/alkalis) combined with self-manufactured fittings extended service life to 30+ years, cutting maintenance costs by 40%.

Sludge Transportation in Metallurgy: Self-anchoring joint pipes from agency brands improved wear resistance by 50%, passing 8-grade seismic tests to ensure production safety.

3. Agricultural Water Conservancy

Large Irrigation District Renovation: DN1600 ductile iron pipes replaced traditional concrete pipes, improving water efficiency by 20% and reducing annual maintenance costs by 35% with enhanced soil subsidence resistance.

Hilly Area Irrigation Network: Flexible joints adapted to terrain undulation, increasing construction efficiency by 40% and reducing km-cost by 12%.

4. Fire Protection & Emergency Systems

Fire Risers in Super High-rises: Self-manufactured self-anchoring joint pipes passed 8-grade seismic tests, applied in a 300m landmark building, improving riser installation efficiency by 40%.

Industrial Park Fire Ring Network: DN2000 pipes with 40bar pressure resistance and corrosion resistance met long-term static requirements, certified by FM.

5. Special Scenarios

Trenchless Pipe Jacking Project: Agency-brand DN2600 jacking pipes used in Zhengzhou Wulongkou WWTP, achieving ±2cm jacking precision and shortening construction duration by 30%.

High-pressure Gas Transmission: Custom FBE-coated pipes passed 10MPa pressure tests, applied in West-East Gas Pipeline branches, doubling service life compared to steel pipes.

V. Manufacturing Processes and Quality Control

Centrifugal Casting: Water-cooled metal mold centrifuges ensure uniform wall thickness (tolerance ≤±0.15mm) and smooth inner surface (K=0.03mm).

Rigorous Testing: 100% hydrostatic testing (for at least 15 seconds), non-destructive flaw detection, and chemical composition analysis to meet international standards.

Customization Services: Support special diameters, coatings (e.g., high-temperature resistant, antibacterial lining), and joint types; provide DFM analysis and tailored quotations.

VI. After-sales Service and Supply Chain Assurance

Installation Support: On-site technical guidance for trench design and joint sealing optimization in complex geological conditions.

Quality Assurance: 5-year warranty, lifetime maintenance, and 24-hour emergency response. Free replacement within 48 hours for joint leakage issues as seen in a municipal project.

Complete Fittings: Offer a full range of fittings (elbows, tees, valves) for system compatibility; localized production of DN3000 fittings reduces lead time by 50%.

VII. Agency Business and Resource Integration

1. Brand Portfolio and Certifications

Agency Brands: Partner with top domestic manufacturers like Xinxing Ductile Iron Pipes, Benxi Steel, Guoming Pipes, all certified by DNV GL and SGS, compliant with ISO 2531 and AWWA C151.

Special Solution: Agency-brand DN3000 water-based epoxy-sealed ductile iron pipes fill domestic technical gaps for high-pressure heavy-load applications.

2. Supply Chain and Delivery

Warehouse Network: 5 major storage centers in North, East, and South China, stocking DN80-DN3000 products for 48-hour delivery of urgent orders.

Digital Management: ERP-integrated inventory for self-manufactured and agency products, visualizing order-production-logistics for 30% shorter lead times.

VIII. Five Reasons to Choose Us

Full-value Chain Coverage: Self-manufacturing + agency model covers DN80-DN3000 diameters and K7-K9 pressure grades for all scenarios from municipal mains to fire branch pipes.

Rapid Response: 48-hour delivery for urgent orders; turnkey solutions for design-production-installation of complex projects.

Cost Optimization: Customized "self-manufacturing + agency" hybrid solutions via scale purchasing, reducing costs by 15%-25%.

Global Service Standards: Export to 50+ countries, serving projects in the US, Australia, Canada, and Saudi Arabia; providing multilingual technical documentation and international certifications.

Immediate action: Submit the form online, fill out your ductile iron pipes application or send an email to: zbw@tiegu.net

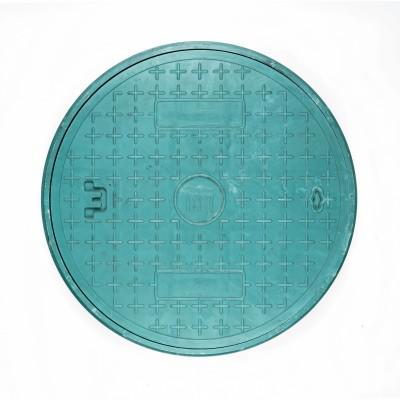

Photos

en

en  fra

fra  de

de  ru

ru  ara

ara  gle

gle  it

it  jp

jp  kor

kor  th

th  zh

zh