Professional Cylinder Head Manufacturer | Custom Diesel Cylinder Head Solutions & Global Supply

Professional engine cylinder head manufacturer offering custom diesel, aluminum alloy, and cast iron cylinder heads. Products include Dongfeng Cummins, Foton Cummins series, using sand/low-pressure casting, compliant with IATF 16949 & IMO standards. Annual capacity >500,000 units, custom orders up to 10 tons. Serving commercial vehicles, marine, and construction machinery. Contact for DFM analysis & quotes! Email: zbw@tiegu.net

Introduction

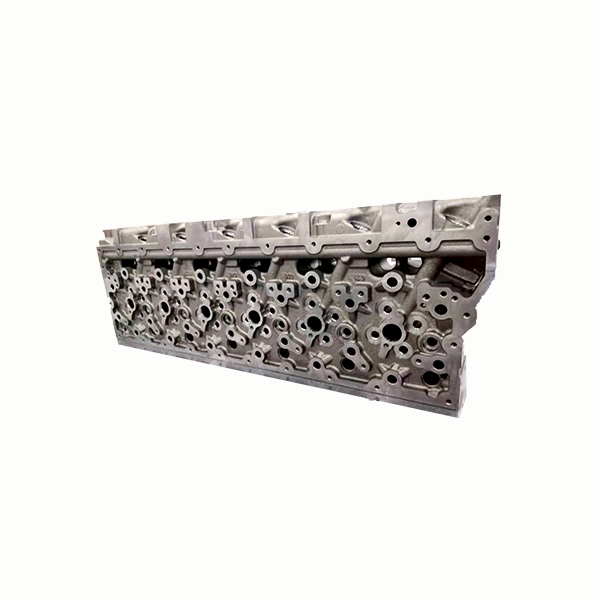

I. What is an Engine Cylinder Head?

An engine cylinder head is a core engine component that seals the top of the cylinder block, forming the combustion chamber and providing mounting support for critical parts like valve trains and fuel injectors. As a leading diesel cylinder head manufacturer, we ensure precision machining for optimal sealing, heat dissipation, and airflow efficiency, suitable for turbocharged and naturally aspirated engines—particularly optimized for high-load applications in commercial vehicle and marine engine cylinder heads. Our products pass high/low-temperature cycle tests, complying with ASTM A159 (aluminum alloy) and DIN EN 1561 (cast iron) standards.

II. Cylinder Head Product Series & Models

Commercial Vehicle Diesel Cylinder Heads

Marine Engine Cylinder Heads

Aluminum Alloy Cylinder Heads

Customization Service: Click to submit your request—our casting engineers will respond within 1 business day.

III. Cylinder Head Classification & Materials

| Material Type | Typical Products | Key Advantages | Applications |

|---|---|---|---|

| Aluminum Alloy | A356-T6 Cylinder Head | Lightweight (40% lighter than cast iron), excellent heat dissipation | Gasoline engines, light-duty diesels |

| Cast Iron | HT300 Cylinder Head | High strength, corrosion resistance, cost-effective | Heavy-duty diesels, commercial vehicles |

| Vermicular Graphite Iron (CGI) | CGI Marine Cylinder Head | 50% improved fatigue resistance, ideal for high-frequency vibration | Marine engines, generator sets |

Need help selecting materials? Submit your query—our engineers will respond within 1 business day.

IV. Key Components of Diesel Cylinder Heads

V. Tiegu Cylinder Head Advantages

Reliable Commercial Vehicle Cylinder Heads

Professional Marine Cylinder Heads

Innovative Aluminum Alloy Cylinder Heads

VI. Manufacturing Processes

Sand Casting for Diesel Cylinder Heads

Nondestructive Testing for Marine Cylinder Heads

VII. Application Fields

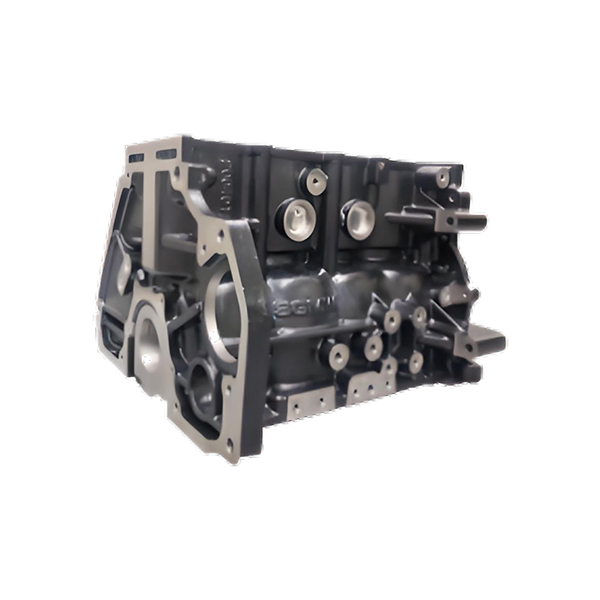

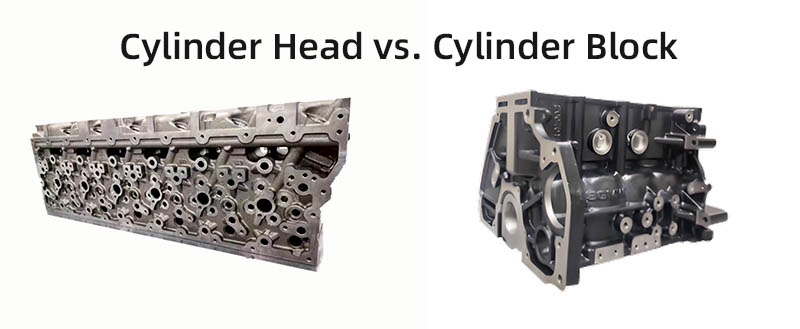

VIII. Cylinder Head vs. Cylinder Block: Core Differences

| Feature | Cylinder Head | Cylinder Block |

|---|---|---|

| Function | Seals cylinder, controls airflow/fuel | Supports pistons/crankshaft, forms engine structure |

| Materials | Aluminum alloy/cast iron/CGI | Gray cast iron/aluminum (lightweight) |

| Weight | 15-150kg (passenger vehicles-marine) | 50-500kg (passenger vehicles-heavy machinery) |

| Key Processes | Valve seat insertion, high-precision surfacing | Cylinder honing, crankshaft bearing boring |

| Failure Modes | Thermal fatigue cracks, valve seat wear | Cylinder bore deformation, water jacket leaks |

Tiegu also supplies cylinder block castings—click here for details.

IX. Contact Us for Cylinder Head Quotes

✅ Diesel cylinder heads (heavy/light duty)

✅ Marine engine cylinder heads (commercial/yacht)

✅ Aluminum alloy cylinder heads (gasoline/hybrid)

✅ Commercial vehicle cylinder heads (trucks/machinery)

✔️ Customized quotes within 24 hours

✔️ Free DFM (Design for Manufacturing) analysis

✔️ Full technical support for sample testing

Photos

-

Leading Crankshaft Manufacturers | Custom & Marine Solutions | Global Supply

-

-

Professional Steering Knuckle Manufacturer | Custom Automotive Knuckles | Global Supply Expert

-

Professional Brake Disc Manufacturer | Custom Automotive Parts | Global Supply Expert

-

Leading Hub Units & Wheel Hubs Manufacturers | Custom & Marine Solutions | Global Supply

-

-

-

en

en  fra

fra  de

de  ru

ru  ara

ara  gle

gle  it

it  jp

jp  kor

kor  th

th  zh

zh