Professional Brake Disc Manufacturer | Custom Automotive Parts | Global Supply Expert

Our brake discs are core components meticulously engineered to enhance vehicle braking performance and driving safety. Leveraging advanced materials and precision manufacturing processes, they are designed for applications in passenger cars, commercial vehicles, and high-performance racing segments. As a critical element of braking systems, our products achieve stable and efficient braking performance under various road conditions through optimized structural design, superior heat dissipation, and enhanced wear resistance. This not only ensures consistent stopping power but also extends service life and reduces maintenance costs.

Introduction

1. What is a Brake Disc?

A brake disc (Brake Disc/Disc Brake Rotor) is the core safety component of a vehicle's braking system, converting kinetic energy into thermal energy through friction with brake pads to achieve deceleration. As a leading supplier in automotive castings, we utilize high-rigidity gray cast iron (HT250/G3000) and carbon fiber-reinforced ceramic composite materials (C/SiC) to ensure exceptional thermal fade resistance and durability under extreme conditions.

2. Key Features of TIEGU Brake Discs

① Precision Machining Technology

CNC-machined for ≤0.015mm surface flatness, minimizing brake judder and noise.

Dynamic balancing eliminates vibration at high speeds, enhancing driving comfort.

② Efficient Heat Dissipation Design

Innovative venting structures (straight/curved slots, drilled patterns) improve airflow, boosting cooling efficiency by 30%+ to prevent thermal fade.

Lightweight designs (selected models) reduce unsprung mass while maintaining strength, optimizing vehicle handling.

③ Low Noise & Eco-Friendly Materials

Optimized friction surface textures reduce sharp braking noises, meeting EU ECE R90 quiet standards.

Asbestos-free brake materials ensure environmental safety and compliance with global regulations.

3. Product Categories & Material Specifications (Brake Disc Types & Materials)

| Type | Material | Application | Operating Temperature Range |

|---|---|---|---|

| Solid Brake Disc | HT250 Gray Cast Iron | Economy passenger cars | -40°C ~ 500°C |

| Vented Brake Rotor | G3000 Ductile Iron | High-performance cars/trucks | -50°C ~ 650°C |

| Drilled/Slotted Disc Brake Rotor | High-Carbon Alloy Steel | Racing/modified cars | -30°C ~ 800°C |

| Carbon-Ceramic Brake Disc | C/SiC Ceramic Matrix Composite | Supercars/high-speed trains/aircraft | -60°C ~ 1200°C |

4. Key Structural Components of Brake Discs (Anatomy of a Disc Brake Rotor)

Friction Ring: Dual-sided working surface with laser-cladded wear-resistant coating.

Cooling Fins: Patented flow-guide slots improve cooling efficiency by 20%.

Hub Flange: CNC-machined to ensure dynamic balance grade G6.3.

Mounting Holes: Compatible with ISO/DIN/JIS fastening standards.

5. Factors Affecting Brake Disc Replacement Costs (Brake Rotor Pricing Drivers)

Material grade (cast iron vs. carbon-ceramic price differential: 5-8x).

Surface treatment (plating, laser texturing, etc.).

OEM certification requirements for specific vehicle models.

Volume-based pricing discounts for bulk orders.

6. Brake Disc vs. Brake Drum Performance Comparison

| Parameter | Brake Disc (Disc Brake Rotor) | Brake Drum |

|---|---|---|

| Heat Dissipation | ★★★★★ | ★★★☆ |

| Maintenance Ease | ★★★★☆ | ★★★ |

| Water Immersion Performance | ★★★★ | ★★☆ |

| Service Life | 80,000-120,000 km | 50,000-80,000 km |

7. Application Scenarios (Typical Use Cases for Brake Discs)

① Passenger Vehicles (Cars, SUVs, EVs)

Urban Driving: Frequent stop-and-go traffic requires durable, low-noise, and minimal-dust brake discs.

Highway Cruising: Stable heat dissipation for sustained braking at 100-120 km/h.

Electric Vehicles: Optimized for regenerative braking compatibility and corrosion resistance (EVs lack engine heat to dry brake discs).

② Commercial Vehicles (Trucks, Buses, Trailers)

Mountain Descents: Vented/drilled brake discs prevent brake fade during prolonged downhill braking.

Heavy Loads: Thicker discs (32-40mm) with high-carbon alloy can handle 3-5x normal payloads.

Fleet Operations: Cost-effective gray cast iron brake discs with extended lifespan (100,000+ km).

③ Performance & Motorsports

Track Racing: Slotted/carbon-ceramic brake discs withstand 800°C+ temperatures during hard braking.

Drifting: Cross-drilled designs dissipate heat rapidly between cornering maneuvers.

Rally/Off-Road Racing: Coated discs resist impact from mud, water, and stones.

④ Specialized Equipment

Trains/Subways: Composite discs for high-speed friction (200-300 km/h).

Wind Turbines: Oversized brake discs for emergency rotor blade braking.

Mining Vehicles: Ultra-thick (50mm+) discs with tungsten-reinforced layers.

⑤ Regional Adaptations

Cold Climates: Anti-snow coatings prevent disc surface icing.

Coastal Regions: Corrosion-resistant treatments (galvanized) for saltwater exposure.

8. Why Choose TIEGU as Your Brake Disc Supplier?

① Full Industrial Chain Control

Pig Iron Smelting: Self-operated blast furnace with 300,000 tons/year capacity, sulfur/phosphorus content ≤0.03% (50% better than national standards).

In-House Casting & Machining: Full control over gray/ductile iron production, reducing outsourcing costs by 12-18%.

7-Day Delivery Cycle: From molten iron to finished brake discs.

② Quality Assurance

12-Step Inspection: From raw material to finished product, including X-ray flaw detection, dynamic balancing tests, and salt spray corrosion resistance testing.

Warranty & Support: 2-year/60,000 km warranty, one-on-one technical consulting, and rapid replacement services.

③ Customization & Global Certifications

Tailored Solutions: Customizable brake systems based on vehicle type, driving habits, and usage scenarios.

Global Certifications: Products meet German TÜV, US DOT, and other international standards, Bestseller in European, American, and Southeast Asian markets (widely sold in European, American, and Southeast Asian markets).

Photos

-

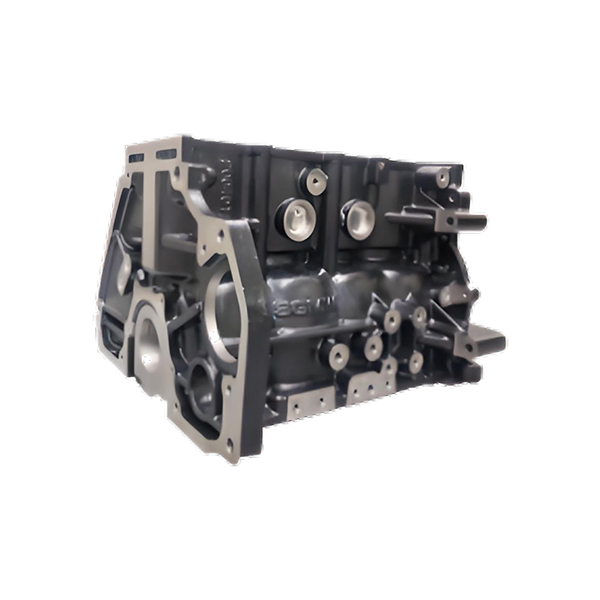

Leading Crankshaft Manufacturers | Custom & Marine Solutions | Global Supply

-

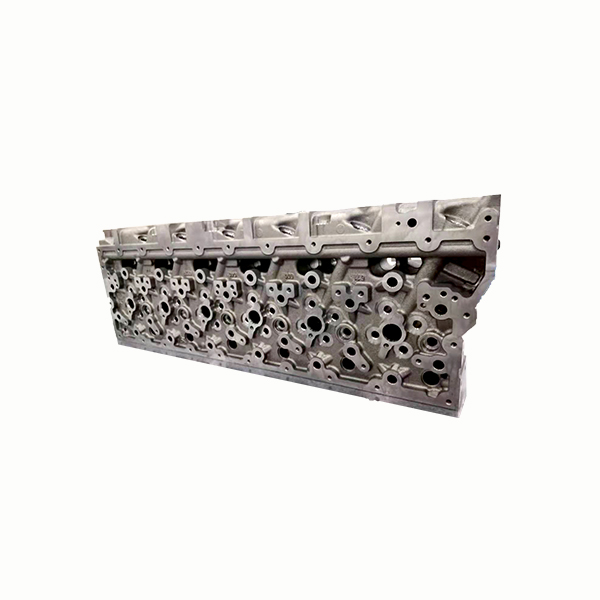

Professional Cylinder Head Manufacturer | Custom Diesel Cylinder Head Solutions & Global Supply

-

-

Professional Steering Knuckle Manufacturer | Custom Automotive Knuckles | Global Supply Expert

-

Leading Hub Units & Wheel Hubs Manufacturers | Custom & Marine Solutions | Global Supply

-

-

-

en

en  fra

fra  de

de  ru

ru  ara

ara  gle

gle  it

it  jp

jp  kor

kor  th

th  zh

zh