Leading Hub Units & Wheel Hubs Manufacturers | Custom & Marine Solutions | Global Supply

As a leading global manufacturer of automotive wheel hub units and wheel hubs, we specialize in the R&D and production of ductile iron, forged steel, and aluminum alloy wheel hubs, catering to passenger vehicles, commercial vehicles, and construction machinery. Leveraging in-house pig iron resources and strategic partnerships with hundreds of domestic foundries, we deliver cost-effective, maintenance-free wheel hub units and lightweight customized solutions. Certified to IATF 16949 and ISO 9001, we serve global clients, including Bosch and ZF, with an annual production capacity exceeding 500,000 units. We support single-piece orders and custom requirements up to 1000Kg, ensuring stable supply and driving vehicle performance through technological innovation.

Introduction

Wheel Hub Units & Wheel Hubs Product Introduction

— High-Strength, Precision Manufacturing for Reliable Global Driving Solutions

I. What Are Wheel Hub Units & Wheel Hubs?

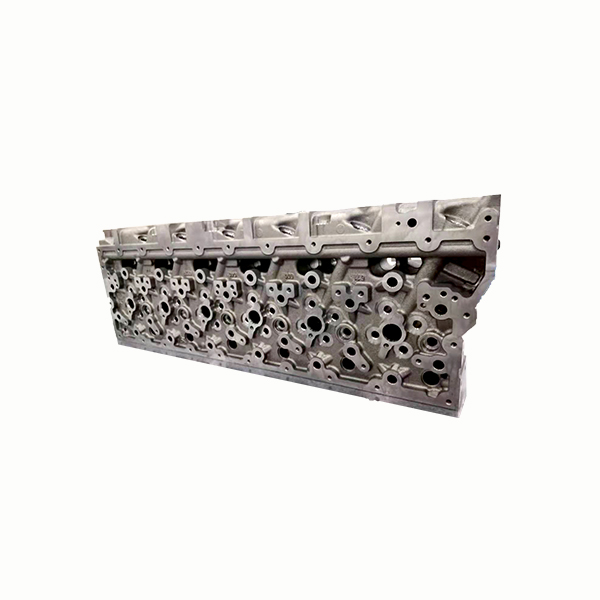

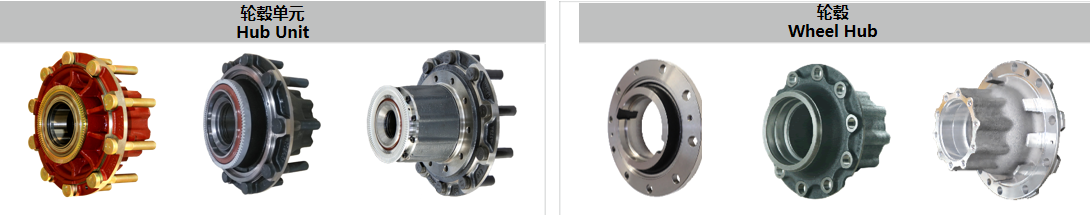

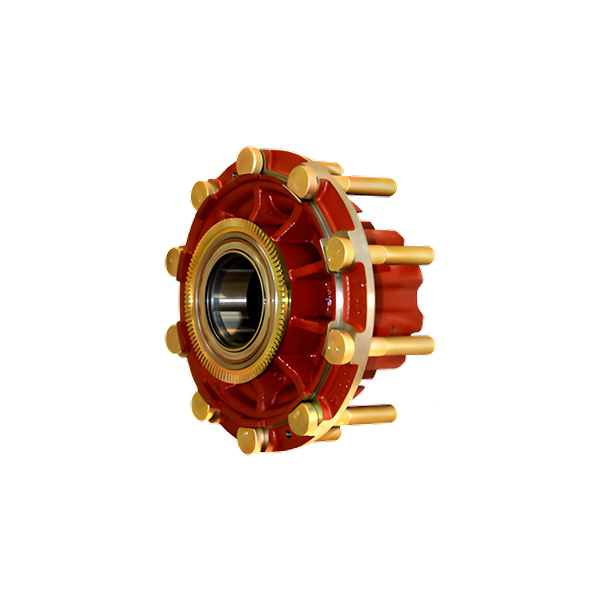

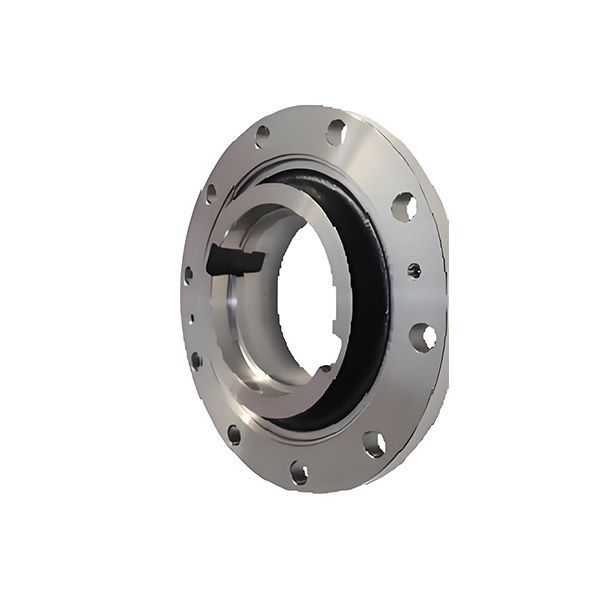

Wheel Hub Unit: A precision assembly integrating bearings, hubs, and sealing components, responsible for connecting the wheel to the axle, bearing dynamic vehicle loads, and ensuring smooth rotation.

Wheel Hub: The core component for wheel mounting, cooperating with brake discs and bearings to transmit driving force and support the vehicle’s weight.

As a global leader in automotive components manufacturing, we specialize in R&D and production of wheel hub units and wheel hubs. Our products comply with IATF 16949 automotive industry standards and ISO 9001 quality systems, serving passenger cars, commercial vehicles, construction machinery, and specialty vehicles.

Wheel Hub Structure & Key Parameters

Five Components:

Rim: Supports the tire.

Spokes: Connect the hub to the axle.

Offset (ET Value): Adjusts wheel track width.

Drop Center: Mounting surface for the tire.

Valve Hole: For tire inflation.

Parameter Matching:

Diameter (inch): 15–22-inch mainstream sizes impact tire aspect ratio and handling (larger sizes improve grip but increase fuel consumption).

PCD (Pitch Circle Diameter): e.g., 5×114.3 (5 bolts/114.3mm PCD) must strictly match original vehicle data for safety.

Offset (ET Value): Determines wheel protrusion/recession; common ET45, with ±3mm tolerance for modifications.

II. Core Functions & Value of Wheel Hub Units & Wheel Hubs

Efficient Power Transmission:

Low-friction bearing design reduces energy loss, enhancing fuel efficiency.

Safe Load-Bearing:

High-strength alloy materials (e.g., ductile iron, forged steel) withstand extreme loads and impacts.

Long Lifespan & Low Maintenance:

Integrated sealing technology prevents contaminant ingress, extending service life to over 300,000 km.

III. Classification & Materials of Wheel Hub Units & Wheel Hubs

Classification:

By Structure: Split-type wheel hub units, integrated wheel bearing units (Gen 1–Gen 3).

By Application: Lightweight passenger car hubs, heavy-duty commercial vehicle hubs, corrosion-resistant construction machinery hubs.

Materials:

Forged Steel: High strength and toughness for heavy-duty/high-performance vehicles.

Aluminum Alloy: Lightweight design for improved fuel economy.

Ductile Iron: Balances cost and strength for standard passenger cars.

IV. Key Manufacturing Processes

Precision Forging:

Multi-directional die forging enhances material density and fatigue resistance.

Optimized Heat Treatment:

Controlled quenching + tempering ensures balanced hardness and toughness.

Automated Assembly:

Robot-assisted bearing and sensor pressing achieves ±0.01mm precision.

| Process Type | Principle | Advantages | Typical Applications |

|---|---|---|---|

| Gravity Casting | Liquid metal gravity molding | Low cost (¥300–500) | OEM for economy vehicles |

| Low-Pressure Casting | 0.1MPa precision molding | 20% strength gain, <1% porosity | Standard for mid-to-high-end cars |

| Forging | 1,000-ton press extrusion | 30% weight reduction, 50% impact resistance boost | Performance cars/premium mods |

Surface Treatments & Customization

Baking Paint: Electrophoretic primer + high-temp baking for 5+ years of color retention; supports matte, metallic, and 10+ finishes.

Electroplating: ≥20μm pure chrome layer, >500h salt spray resistance; used in luxury models (e.g., Mercedes-Benz S-Class options).

Lightweight Design: Spinning reduces rim thickness from 6mm to 4mm, saving 1.5kg per unit and boosting EV range.

V. Application Fields

Passenger Cars: Lightweight designs for NEVs, supporting ABS/ESP sensor integration.

Commercial Vehicles: Heavy-duty designs for trucks, buses, and trailers.

Specialty Machinery: Anti-corrosion coatings for agricultural and mining equipment.

Selection & Maintenance Guidelines

Matching Principles: Prioritize PCD and offset consistency with original vehicles to avoid high-speed vibrations.

Fault Diagnosis:

Noise: Inspect bearing raceway pitting (visible to the naked eye) or spoke cracking (ultrasonic testing).

Vibration: Recalibrate dynamic balance (<5g·cm tolerance), replace deformed rims.

Lifespan Management: Replace hub unit grease every 80,000 km; apply anti-oxidation treatment to electroplated hubs every 2 years.

VI. Why Choose Tiegu as Your Wheel Hub Unit & Wheel Hub Supplier?

1. Raw Material Cost Advantages

Self-Supplied Pig Iron: Direct group supply reduces intermediate costs by 15–20%. Integrated supply chain ensures material stability and production continuity (e.g., aluminum water direct supply reduces oxidation loss for aluminum hubs).

Material Optimization: Proprietary creep-resistant alloys (e.g., ductile iron, magnesium-aluminum alloys) improve high-temperature deformation resistance by 15%, ideal for heavy-load/high-braking scenarios.

2. Scalable Supply Capacity

Extensive Partnership Network: Strategic alliances with 100+ domestic foundries form a "casting industrial cluster," enabling rapid response to diverse customer needs (standard parts, custom shapes, specialty materials like carbon fiber composites).

Production Capacity: Annual output exceeds 600,000 tons, supporting monthly delivery of 50,000+ hub units for passenger cars, commercial vehicles, and construction machinery.

3. Customization Services & Proven Case Studies

Design Flexibility: Generative design technology creates 1,000+ spoke styles validated via simulation; additive manufacturing enables complex structures (e.g., hollow carvings, lightweight topology optimization).

Benchmark Collaborations: Delivered 2M+ maintenance-free hub assemblies to Bosch, ZF, etc., with <0.1% failure rate; developed lightweight forged hubs for Lotus, Jiyue, etc., achieving 30% weight reduction while maintaining ≥275MPa yield strength.

VII. Contact Us

📧 E-mail: zbw@tiegu.net

📍 Address: 19th Floor, Building 1, Jinnuode Technology Incubator, No. 1686 Xiyou Road, High-tech Zone, Hefei City, Anhui Province, China

🌐 Online Form: Submit requirements for a technical solution and quote within 2 hours.

Service Commitments

Rapid Response: Technical solutions and quotes within 2 hours; hub unit/wheel hub samples in 72 hours; global logistics (Europe/North America: 7–10 days).

Joint R&D Support: Collaborate to build labs, participate in early vehicle design stages, and provide hub-suspension system optimization.

Tiegu – Driving the Future with Precision Manufacturing, Delivering Safe, Durable Wheel Hub Solutions for Your Vehicles!

Photos

-

Leading Crankshaft Manufacturers | Custom & Marine Solutions | Global Supply

-

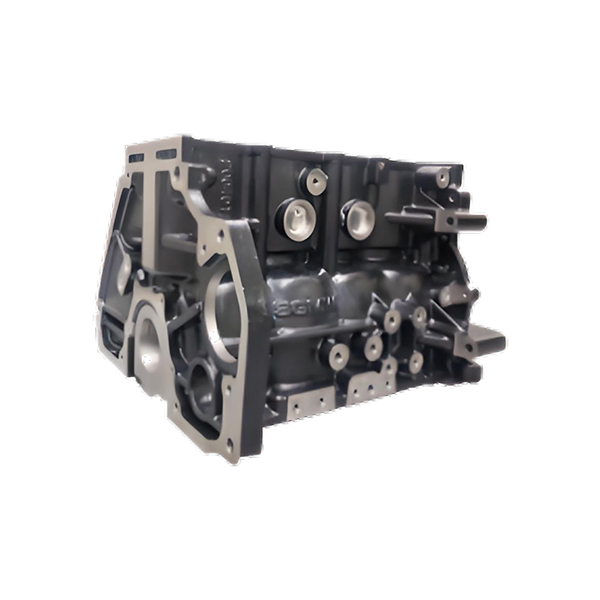

Professional Cylinder Head Manufacturer | Custom Diesel Cylinder Head Solutions & Global Supply

-

-

Professional Steering Knuckle Manufacturer | Custom Automotive Knuckles | Global Supply Expert

-

Professional Brake Disc Manufacturer | Custom Automotive Parts | Global Supply Expert

-

-

-

en

en  fra

fra  de

de  ru

ru  ara

ara  gle

gle  it

it  jp

jp  kor

kor  th

th  zh

zh