Professional Steering Knuckle Manufacturer | Custom Automotive Knuckles | Global Supply Expert

Precision Steering Knuckle Solutions for Enhanced Vehicle Control As a leading steering knuckle manufacturer and forged automotive components supplier, we deliver IATF 16949 and ISO 9001-certified steering knuckles for passenger cars, heavy-duty trucks, agricultural machinery, and off-road vehicles. Core Capabilities ✅ Advanced Manufacturing: Iron mold casting & precision forging for steering knuckle blanks and finished products. ✅ Custom Expertise: Support 500Kg custom steering knuckles with optimized kingpin geometry and bearing seat designs. ✅ Global Partnerships: Annual exports of 80,000+ units, serving Volvo, Daimler, and leading construction equipment brands. ✅ Vertical Integration: In-house ductile iron casting ensures material consistency for critical safety components. Industry Applications Commercial Vehicles: Forged steel steering knuckles with 1,000MPa tensile strength for mining trucks. EV/Hybrids: Lightweight aluminum knuckles (A356-T6) reducing unsprung mass by 20%. Agriculture: Corrosion-resistant ductile iron knuckles for tractors operating in high-humidity environments.

Introduction

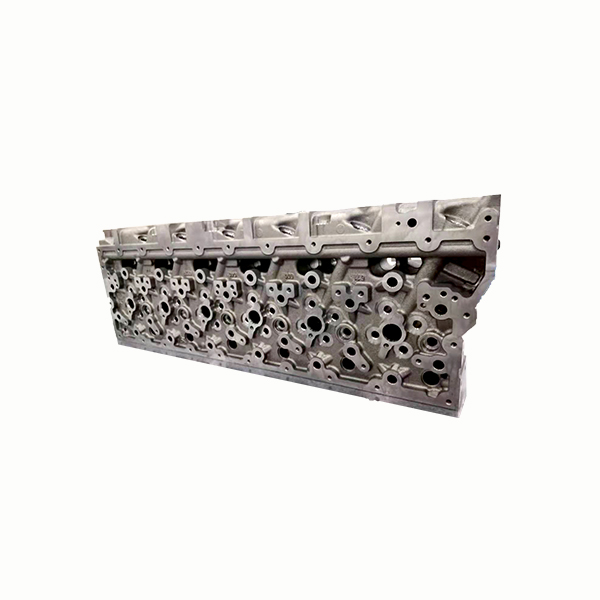

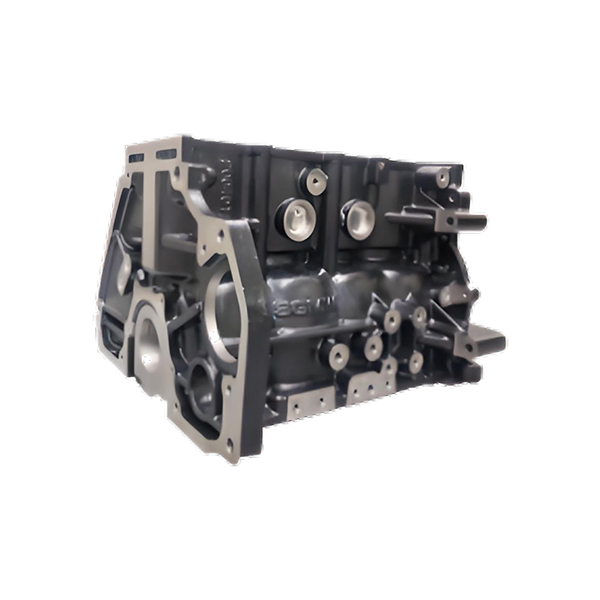

I. Knuckle Product Overview

The steering knuckle (or wheel knuckle) is a critical load-bearing and force-transmission component in automotive steering systems. Acting as the central hub connecting the wheel, steering mechanism, and suspension, it directly handles steering force transfer, road impact absorption, and vehicle weight support. Its performance directly impacts handling stability, driving safety, and ride comfort.

Our Expertise: As a leading steering knuckle manufacturer, we deliver IATF 16949 and ISO 9001-certified knuckles for passenger cars, commercial vehicles, and specialty vehicles, engineered with high-strength materials and advanced manufacturing processes.

II. Steering Knuckle Types & Material Selection

| Knuckle Type | Material | Applications |

|---|---|---|

| Cast Steering Knuckle | Ductile Iron (QT500-7/QT600-3) | Passenger Cars, Light Trucks |

| Forged Steering Knuckle | Alloy Steel (42CrMo/4140) | Heavy-Duty Trucks, Construction Machinery |

| Lightweight Knuckle | Aluminum (A356-T6) | EVs, High-Performance Race Cars |

III. Key Features & Technical Advantages of Automotive Knuckles

Precision Engineering for Steering Knuckles

3D FEA-optimized designs balance strength-to-weight ratios, minimizing deformation under extreme conditions (sharp turns/off-road impacts).

Integrated kingpin axis, wheel bearing seats, and brake caliper interfaces ensure accurate torque transfer and multi-component synergy.

Advanced Knuckle Materials & Manufacturing

Precision Casting: Lost foam (EPC) or high-pressure casting reduces internal shrinkage to ≤Grade 1 (ASTM A247).

Heat Treatment: Normalizing + tempering or ADI process achieves HRC45-50 surface hardness with optimized core toughness.

Machining: 5-axis CNC ensures ±0.02mm precision on critical dimensions (kingpin bore, bearing seats).

Ductile iron (QT500-7/QT600-3) or low-alloy steel (42CrMo) with tensile strength ≥600MPa, elongation ≥12%, and -40°C~150°C operational range.

Core Materials:

Production Processes:

Durability & Reliability Testing

Corrosion Resistance: 720+ hours salt spray testing (ISO 9227), coating adhesion Grade 1 (ISO 2409).

Fatigue Performance: 1 million cycle bench tests (equivalent to 300,000 km driving), zero crack initiation.

Dynamic Validation: K&C rig-tested for steering stiffness and caster angle consistency, meeting OEM specifications.

IV. Main Components of a Steering Knuckle

Knuckle Arm: Connects to tie rods for steering force transmission.

Kingpin Bore: Mounts suspension upper/lower control arms.

Wheel Bearing Housing: Supports wheel rotation via integrated bearings.

Brake Mounting Surface: Secures brake calipers and disc/drum systems.

V. Factors Influencing Steering Knuckle Replacement Costs

Material & Process: Forged knuckles cost 30-50% more than cast but extend service life.

Design Complexity: Lightweight integrated structures increase machining challenges.

Certifications: OE-compliant knuckles command 15-20% price premium.

VI. Steering Knuckle vs. Suspension Control Arm: Critical Differences

| Component | Primary Role | Load Profile | Material | Failure Modes |

|---|---|---|---|---|

| Steering Knuckle | Wheel alignment & force transfer | Multi-axis loads (longitudinal/lateral/vertical) | QT700/42CrMo | Fatigue cracks, kingpin wear |

| Control Arm | Suspension geometry & damping | Vertical compression/tension | A356-T6 aluminum/steel | Bushing degradation, ball joint wear |

VII. Steering Knuckle Applications & Compatibility

Vehicle Coverage: Compatible with sedans, SUVs, EVs, and light commercial vehicles (MacPherson/double-wishbone suspensions).

Customization: Pre-machined sensor mounts (steering angle/wheel speed sensors) for ADAS integration.

Extreme Conditions: -40°C low-temperature impact and 120°C thermal endurance certified for polar/desert environments.

VIII. Why Choose Tiegu as Your Steering Knuckle Supplier?

Full-Scale Production: In-house pig iron smelting ensures material consistency (C:3.2-3.8%, Si:2.0-2.5%).

Global OEM Partnerships: 80,000+ annual exports, serving Volvo, Daimler, and Tier 1 suppliers with 50-500kg custom knuckles.

Quality Assurance: CMM (±0.01mm), magnetic particle inspection, and 720h+ salt spray testing.

R&D Support: CAE simulation, rapid prototyping, and DV/PV validation to slash development timelines by 30%.

IX. Contact Us for Custom Steering Knuckle Solutions

✉️ Email: zbw@tiegu.net

📍 Address: 19F, Building 1, Jinnuode Tech Incubator, 1686 Xiyou Rd, Hefei Hi-Tech Zone, Anhui, China

📝 Online Form: Submit Requirement

(2-hour response guarantee with technical proposals & quotes)

0

Photos

-

Leading Crankshaft Manufacturers | Custom & Marine Solutions | Global Supply

-

Professional Cylinder Head Manufacturer | Custom Diesel Cylinder Head Solutions & Global Supply

-

-

Professional Brake Disc Manufacturer | Custom Automotive Parts | Global Supply Expert

-

Leading Hub Units & Wheel Hubs Manufacturers | Custom & Marine Solutions | Global Supply

-

-

-

en

en  fra

fra  de

de  ru

ru  ara

ara  gle

gle  it

it  jp

jp  kor

kor  th

th  zh

zh