Ductile Iron Pipes: A Professional's Technical Overview

2025-11-04 17:10:41 hits:0

TL;DR

Ductile iron pipe is a modern, advanced form of cast iron pipe used extensively for potable water and wastewater infrastructure. Its unique manufacturing process creates a spheroidal graphite structure, giving it superior strength, ductility, and impact resistance compared to traditional cast iron. Recognized as an industry standard, ductile iron pipes are valued for their proven durability, ease of installation, and an expected service life that can exceed 100 years with proper corrosion protection.

What Is Ductile Iron Pipe and Its Primary Applications?

Ductile iron pipe is a direct development from earlier cast iron pipe, engineered to overcome its predecessor's brittleness. The key to its performance lies in its metallurgy. During production, small amounts of magnesium are added to the molten iron, which transforms the graphite from sharp flakes into spheroidal, or nodular, shapes. This change in microstructure eliminates the inherent stress points found in gray cast iron, resulting in a material that is not only strong but also remarkably ductile—meaning it can deform under stress without fracturing. This property is crucial for withstanding pressure surges, soil movement, and impacts during shipping and installation.

The manufacturing process typically involves centrifugal casting, where molten iron is spun inside a cylindrical mold to form the pipe. This method ensures a consistent wall thickness and a dense, uniform structure. The exterior of the pipe often has a textured, "bumpy" surface, known as a peen pattern. This pattern is intentionally machined into the mold to help the molten iron grip the surface during the high-speed spinning process, ensuring the pipe wall forms correctly. An added benefit of this texture is that it increases frictional resistance with the surrounding soil, enhancing stability once buried.

Ductile iron pipe is the material of choice for a wide range of critical applications. Its primary use is in municipal infrastructure for the transmission and distribution of potable water and the collection of wastewater and sewage. Its strength allows it to handle high internal pressures and significant external loads from deep burial or heavy traffic. Beyond municipal systems, it is also used in industrial applications for transporting slurries, process chemicals, and raw water. Its resilience makes it suitable for demanding conditions, including frozen ground, unstable soils, and areas with high water tables.

Ductile Iron vs. Cast Iron: A Clear Advantage

While both are ferrous materials, the difference in performance is significant. Ductile iron's superior properties make it the modern standard for water systems. The primary distinction is its ductility and resistance to fracture, which directly addresses the main weakness of traditional cast iron.

| Attribute | Ductile Iron Pipe (DI) | Cast Iron Pipe (CI) |

|---|---|---|

| Material Structure | Spheroidal/nodular graphite | Graphite flakes |

| Key Property | High ductility and tensile strength; can bend without breaking | Brittle; prone to fracture under impact or bending stress |

| Impact Resistance | Excellent; withstands handling, installation, and water hammer | Poor; can crack or shatter if dropped or stressed |

| Common Use | Modern water mains, sewer force mains, and industrial pipelines | Older water systems (largely superseded), gravity sewers, and building drainage |

Key Specifications, Sizes, and Industry Standards

To ensure safety, interoperability, and performance, the manufacturing and use of ductile iron pipes are governed by strict industry standards. These standards dictate everything from chemical composition and mechanical properties to dimensions, pressure ratings, and quality control tests. For engineers and contractors, understanding these specifications is critical for selecting the correct pipe for a project's specific requirements, such as operating pressure and burial depth.

In North America, the primary standards are set by the American National Standards Institute (ANSI) and the American Water Works Association (AWWA). For example, ANSI/AWWA C151/A21.51 is the standard for the manufacturing of ductile iron pipe. In Europe, pipes typically conform to ISO 2531 or its derivatives, EN 545 for potable water and EN 598 for sewage. It's important to note that these regional standards are not interchangeable; pipes made to AWWA specifications will not be dimensionally compatible with those made to EN standards.

Ductile iron pipes are available in a wide range of sizes, typically from 3 inches to 64 inches in nominal diameter. A key aspect of standardization is that the outside diameter (OD) for a given nominal size is kept constant. This ensures that standard joints and fittings are compatible across different pressure classes or wall thicknesses. Consequently, as the wall thickness increases for higher pressure ratings, the internal diameter (ID) decreases. This larger-than-nominal ID in standard pressure classes is an advantage, as it reduces head loss and can lead to significant energy savings in pumping costs over the pipeline's life. For global projects requiring robust infrastructure solutions, suppliers like Tiegu Export offer certified ductile iron pipes and fittings engineered to exceed international standards for durability and performance.

Common North American Pipe Sizes (ANSI/AWWA C151)

| Nominal Pipe Size (inches) | Outside Diameter (inches) |

|---|---|

| 4 | 4.80 |

| 6 | 6.90 |

| 8 | 9.05 |

| 12 | 13.20 |

| 16 | 17.40 |

| 24 | 25.80 |

Understanding Joint Types and Fittings

The method used to connect individual lengths of ductile iron pipe is fundamental to the integrity and flexibility of a pipeline. Different joint types are designed for specific applications, pressures, and site conditions. The choice of joint affects installation speed, the need for external thrust restraint, and the pipeline's ability to accommodate ground movement.

The most common types of joints include:

Push-On Joint (e.g., Tyton Joint): This is the most widely used joint for underground water and sewer mains. It features a bell end with a pre-installed elastomeric gasket and a plain spigot end. After lubricating the gasket and spigot, the spigot is simply pushed into the bell, creating a quick, reliable, and flexible seal. The number of painted stripes on the spigot (one or two) typically indicates the manufacturer and gasket design but serves the same functional purpose of guiding assembly and deflection.

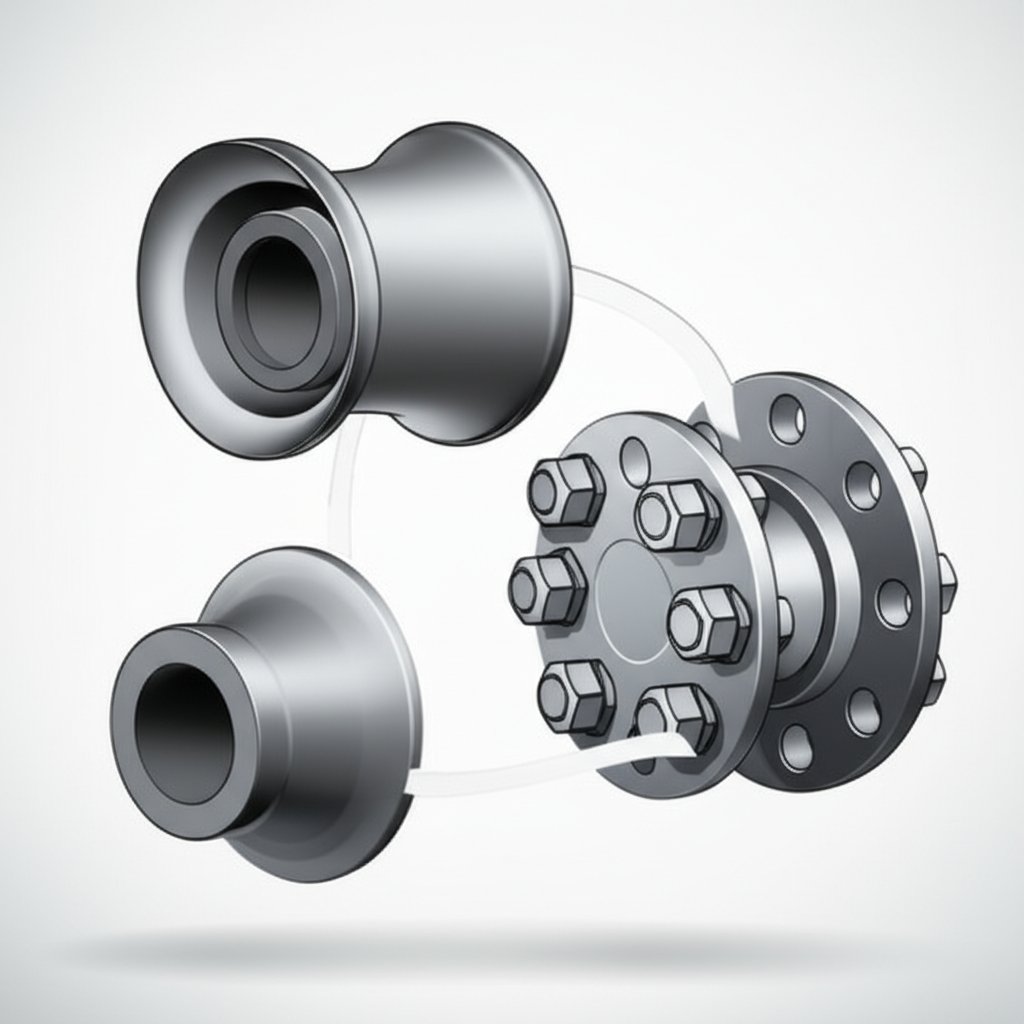

Mechanical Joint (MJ): This joint consists of a bell, a gland, a gasket, and a set of T-head bolts and nuts. The joint is assembled by compressing the gasket into the socket by tightening the bolts. Mechanical joints are often used for connections to fittings, valves, and hydrants. They provide a strong, rigid seal but require more assembly time than push-on joints.

Flanged Joint: Flanged joints create a rigid, bolted connection. A flat, drilled flange is welded or threaded onto each pipe end, and the two flanges are bolted together with a gasket in between. This type of joint is typically used in above-ground applications like treatment plants and pump stations where rigid connections are necessary and disassembly may be required.

Restrained Joint: These joints are designed to prevent separation at bends, tees, and dead ends, eliminating the need for concrete thrust blocks. Various proprietary designs exist, such as TR FLEX®, which use locking segments, welded retainer rings, or special gaskets to mechanically lock the spigot into the bell, allowing the pipeline to withstand axial thrust forces. They are essential in areas with poor soil conditions, on steep slopes, or in seismically active zones.

Corrosion Protection, Durability, and Performance Trade-Offs

While ductile iron is an incredibly strong and durable material, it is a ferrous metal and thus susceptible to corrosion if left unprotected in aggressive environments. This is often cited as its primary disadvantage. However, modern ductile iron pipes are manufactured with sophisticated protection systems that effectively mitigate corrosion and ensure a long service life. The assertion that ductile iron pipe has a lifespan of over 100 years is based on its use with these evolved protection methods.

Internal corrosion and tuberculation (the formation of rust nodules that restrict flow) are prevented by a standard cement-mortar lining. This lining is centrifugally applied during manufacturing, creating a smooth, dense barrier. It protects the iron by physically separating it from the water and by creating a high-pH alkaline environment at the pipe wall, which inhibits corrosion. This simple, proven technology has effectively eliminated tuberculation in modern iron pipes.

External corrosion is managed through a combination of coatings and encasement. The standard practice in North America is to install the pipe with loose polyethylene (PE) sleeving. This plastic tube is wrapped around the pipe during installation, creating a barrier that separates the pipe from corrosive soil and limits the availability of oxygen and electrolytes needed for corrosion to occur. In other parts of the world, pipes may also be coated with a layer of zinc, which provides sacrificial galvanic protection, often followed by a bituminous or epoxy topcoat.

Pros and Cons of Ductile Iron Pipe

Pros

Superior Strength: High tensile strength and impact resistance prevent damage during handling and from traffic loads or water hammer.

Proven Longevity: With modern corrosion protection, service life is expected to exceed 100 years.

Ductility: Ability to bend without breaking makes it resilient to soil shifting and seismic events.

Ease of Installation: Push-on joints allow for fast and efficient assembly in the trench.

Cons

Corrosion Susceptibility: Requires external protection (like PE sleeving) in corrosive soils to achieve its maximum lifespan.

Weight: Heavier than plastic pipe alternatives, requiring heavy machinery for handling and installation.

The Enduring Standard for Water Infrastructure

Ductile iron pipe has firmly established itself as the industry standard for modern water and wastewater systems for compelling reasons. Its unique combination of high strength, impact resistance, and ductility provides a level of reliability and safety that is difficult to match. While susceptible to corrosion like any ferrous material, the development of advanced linings and coatings has effectively mitigated this concern, enabling a proven service life of a century or more.

From the precise engineering of its dimensions and joint systems to its sustainable manufacturing from recycled materials, ductile iron pipe represents a long-term investment in community resilience. For engineers, contractors, and municipalities, its performance characteristics translate into lower life-cycle costs, reduced maintenance, and the assurance of a safe, dependable water supply for generations to come. The continued innovation in jointing technology and corrosion control ensures that it will remain a cornerstone of critical infrastructure projects worldwide.

Frequently Asked Questions About Ductile Iron Pipe

1. What is the main disadvantage of ductile iron pipe?

The primary disadvantage of ductile iron pipe is its susceptibility to corrosion in aggressive soil or water conditions if it is not properly protected. As a ferrous metal, it will rust when exposed to moisture and oxygen. To counteract this, modern pipes are manufactured with protective systems, such as an internal cement-mortar lining to prevent tuberculation and external protection like loose polyethylene encasement to shield against soil corrosion. Without these protective measures, the pipe's lifespan can be significantly reduced.

2. Which is better, cast iron (CI) or ductile iron (DI)?

Ductile iron (DI) is unequivocally better than traditional cast iron (CI) for modern pressure pipeline applications. The key difference is ductility. Ductile iron's spheroidal graphite structure allows it to bend and deform under stress without fracturing, whereas cast iron's flake graphite structure makes it brittle and prone to cracking under impact or soil movement. This makes ductile iron far stronger, more durable, and safer for water and wastewater systems that operate under pressure and are subject to external loads.

en

en  fra

fra  de

de  ru

ru  ara

ara  gle

gle  it

it  jp

jp  kor

kor  th

th  zh

zh