The Truth About K9 and K12 Ductile Iron Pipes: Which One Lasts Longer?

2025-11-03 17:38:09 hits:0

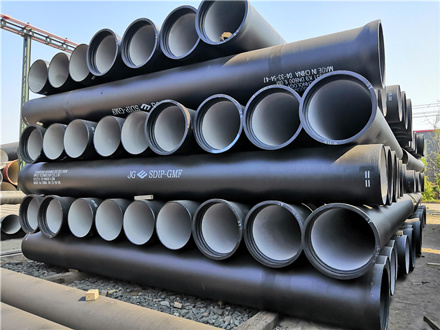

When selecting ductile iron pipes (DIP) for water supply, sewage, or industrial systems, engineers and project managers frequently encounter two common specifications — K9 and K12. These “K-classes” define the wall thickness, pressure rating, and overall strength of the pipe.

Understanding the difference between K9 and K12 ductile iron pipes is essential for choosing the right class that ensures safety, durability, and cost-efficiency.

In this guide, we’ll take a detailed look at their technical parameters, applications, price comparison, and selection advice from a practical engineering perspective.

1. What Does “K-Class” Mean in Ductile Iron Pipes?

The “K” in K9 or K12 refers to a classification system for ductile iron pipes defined by international standards such as ISO 2531, EN 545, and EN 598.

The class number (K7, K8, K9, K10, K12, etc.) corresponds to the pipe wall thickness — the higher the K-number, the thicker the pipe wall and the greater the pipe’s internal pressure capacity.

| Class | Example (DN200) Wall Thickness | Approx. Working Pressure | Typical Applications |

|---|---|---|---|

| K7 | 6.0 mm | 1.0 MPa | Low-pressure irrigation, drainage |

| K9 | 6.3 mm | 1.6 MPa | Standard water distribution |

| K12 | 7.2 mm | 2.5 MPa | High-pressure or mountainous pipelines |

In simple terms:

Higher K = Thicker wall = Higher strength and cost.

2. Structural and Mechanical Differences Between K9 and K12

(1) Wall Thickness and Weight

The most direct difference lies in the wall thickness.

For a pipe of the same nominal diameter (DN), K12 is about 10–20% thicker than K9.

Example for DN200 pipe:

K9 → 6.3 mm wall thickness

K12 → 7.2 mm wall thickness

The thicker wall means higher tensile and internal pressure strength, but also a heavier weight per meter, affecting transportation and installation.

| Specification | K9 | K12 |

|---|---|---|

| Wall thickness (DN200) | 6.3 mm | 7.2 mm |

| Weight (approx.) | 26.3 kg/m | 31.5 kg/m |

| Strength | Moderate | High |

| Handling | Easier | Requires lifting equipment |

(2) Pressure Rating

K12 pipes can handle higher internal and test pressures due to their thicker walls.

They are designed for projects that experience frequent pressure surges or are located in elevated terrain.

| Pressure Type | K9 | K12 |

|---|---|---|

| Working Pressure | 1.6 MPa | 2.5 MPa |

| Test Pressure | 2.0 MPa | 3.0 MPa |

| Safety Factor | Standard | Enhanced |

💡 Tip: If your system includes booster pumps or elevation changes, consider K12 for long-term reliability.

(3) Installation and Handling

Because K12 pipes are heavier, they require mechanical lifting equipment (cranes or pipe handlers) during installation.

K9 pipes, being lighter, are often easier to handle manually, especially for urban water distribution or confined trench work.

However, both classes use the same types of joints:

Push-on (Tyton joint)

Mechanical joint

Flanged joint

(4) Corrosion Protection

Both K9 and K12 pipes receive identical coatings and linings:

Internal lining: Cement mortar lining (to ISO 4179)

External coating: Zinc + Bitumen or Epoxy (to ISO 8179)

Optional: Polyurethane (PU) or epoxy coatings for aggressive environments

Hence, their corrosion resistance and service life (typically 50–70 years) are the same — the difference lies purely in mechanical strength.

3. Applications: When to Use K9 vs K12

| Application Scenario | Recommended Class | Reason |

|---|---|---|

| Municipal water supply | K9 | Standard operating pressure |

| Underground drainage | K9 | Lightweight and cost-efficient |

| Firefighting and industrial water systems | K9 | Sufficient pressure resistance |

| High-pressure transmission mains | K12 | Extra wall thickness for stability |

| Hilly or mountainous terrain | K12 | Handles pressure fluctuations |

| Long-distance or high-head pipelines | K12 | Reduces risk of failure over time |

✅ Rule of thumb:

Choose K9 for normal conditions; choose K12 for demanding or high-pressure environments.

4. K9 vs K12 Ductile Iron Pipe Price Comparison

As of late 2025, the average international price range (FOB China) is:

| Diameter | K9 Price (USD/meter) | K12 Price (USD/meter) |

|---|---|---|

| DN100 | 20–28 | 24–32 |

| DN200 | 30–45 | 35–55 |

| DN300 | 55–75 | 65–85 |

| DN400 | 80–110 | 95–125 |

| DN600 | 140–190 | 170–230 |

Price difference:

K12 is usually 10–20% more expensive than K9 because of extra metal weight and manufacturing cost.

Other factors influencing price:

Coating type (bitumen, epoxy, PU, zinc + bitumen)

Socket type (Tyton, mechanical, flanged)

Order quantity and delivery term (FOB, CIF, DDP)

Country-specific standards and testing requirements

💡 Note: Always specify nominal diameter, class (K9/K12), and coating type when requesting quotations to ensure accurate pricing.

5. Standards and Quality Certifications

Both K9 and K12 ductile iron pipes are manufactured according to international standards:

ISO 2531 – Ductile iron pipes, fittings, accessories for water applications

EN 545 – Ductile iron pipes for potable water

EN 598 – Ductile iron pipes for sewerage

BS EN 15655 / ISO 7186 – for coating and lining requirements

Common quality certifications:

ISO 9001 (Quality Management)

ISO 14001 (Environmental Management)

WRAS or NSF (Drinking Water Safety)

6. Durability and Service Life

Both K9 and K12 have a service life exceeding 50 years, provided proper installation and corrosion protection are ensured.

Their main advantages over PVC or steel pipes include:

Excellent impact resistance

No crack propagation

Natural ductility (can withstand ground movement)

Lower maintenance cost

Environmentally sustainable (fully recyclable)

7. Selecting the Right Class for Your Project

Here’s a practical decision framework:

| Project Condition | Recommended Class |

|---|---|

| Flat terrain, moderate pressure | K9 |

| Short-distance municipal networks | K9 |

| Hilly, uneven terrain | K12 |

| Pumping or high-pressure systems | K12 |

| Uncertain pressure fluctuation | K12 |

| Budget-sensitive project | K9 |

If unsure, you can perform hydraulic calculations based on your design pressure and safety factor to verify whether K9 is sufficient.

8. Conclusion

In summary:

K9 ductile iron pipes are standard class, cost-effective, and suitable for most municipal applications.

K12 pipes are heavy-duty, designed for higher internal pressures, steep terrains, and long transmission pipelines.

Both classes share the same materials, coatings, and connection systems, but differ in wall thickness, weight, and price.

Choosing the right class ensures long-term reliability, safety, and optimal investment efficiency for your water infrastructure project.

9. Contact Us for Ductile Iron Pipe Quotation

As a professional ductile iron pipe manufacturer and exporter, we supply:

DN80–DN2600 sizes

K7, K8, K9, K10, K12 classes

Coatings: Cement mortar, Epoxy, Bitumen, Zinc + Bitumen, PU

Joints: Tyton, Mechanical, Flanged

📧 Email: duanduan@tiegu.net

Our engineering team can recommend the most suitable class and provide detailed quotations and technical drawings based on your project requirements.

en

en  fra

fra  de

de  ru

ru  ara

ara  gle

gle  it

it  jp

jp  kor

kor  th

th  zh

zh