How Does a Ductile Iron Pipe Joint Achieve Sealing?

2026-02-19 07:20:49 hits:0

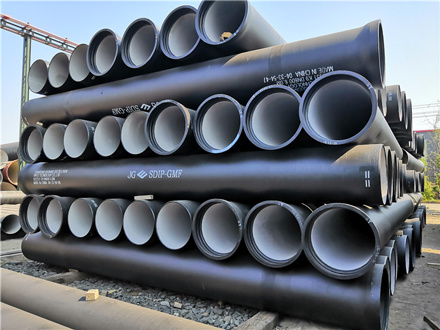

Ductile iron pipes are widely used in municipal water supply, drainage, and pressurized pipeline systems.

One of their most important technical advantages lies in the reliability of their joint sealing mechanism.

But how exactly does a ductile iron pipe joint prevent leakage under pressure?

This article explains:

The mechanical relationship between socket, spigot, and rubber gasket

Why higher internal pressure can improve sealing performance

Why flexible joints are considered safer in real engineering conditions

For a detailed overview of different ductile iron pipe joint types and connection systems, you can refer to our dedicated joint and connection section.

1. Structural Relationship: Socket, Spigot and Rubber Gasket

A typical push-on ductile iron pipe joint consists of three essential components:

Socket (bell end) – designed with a gasket groove

Spigot (plain end) – inserted into the socket

Rubber gasket – positioned inside the groove to create compression

During assembly:

The gasket is seated in the socket groove.

Lubricant is applied evenly.

The spigot is pushed into the socket.

The gasket becomes radially compressed between the two metal surfaces.

Core Sealing Principle

The joint achieves sealing through elastic radial compression of the rubber gasket.

This compression creates:

Continuous circumferential contact

Uniform sealing pressure

Compensation for minor dimensional tolerances

Unlike rigid metal-to-metal sealing, this system relies on stored elastic energy within the compressed gasket.

2. Why Higher Internal Pressure Can Enhance Sealing

Within the design pressure range, ductile iron push-on joints demonstrate a self-enhancing sealing behavior.

When internal water pressure increases:

The pressure pushes the spigot outward slightly

The gasket is pressed more firmly against the sealing surfaces

Contact stress increases proportionally

This phenomenon is often described as a self-energizing sealing effect.

In simplified engineering logic:

Higher internal pressure → Increased gasket contact force → Improved sealing tightness

As long as installation is correct and deflection limits are respected, internal pressure supports rather than weakens sealing performance.

3. Why Flexible Joints Provide Greater Safety

Ductile iron pipe joints are designed as flexible connections rather than rigid mechanical couplings.

This flexibility allows:

Controlled angular deflection

Minor axial displacement

Adaptation to soil settlement

In real engineering environments:

Ground conditions are rarely perfectly stable

Thermal expansion and contraction occur

Minor alignment deviations are common

If joints were rigid, these movements could generate stress concentration, potentially leading to cracking or leakage.

Flexible joints absorb small movements while maintaining gasket compression, significantly improving long-term operational safety.

For comparison between different joint structures, including flexible and restrained designs, refer to the ductile iron pipe joint configuration overview.

4. Installation Still Determines Final Performance

Although the joint design supports pressure-assisted sealing, performance depends on proper installation:

Correct gasket seating

Clean sealing surfaces

Verified insertion depth

Controlled joint deflection

The sealing mechanism functions optimally when mechanical alignment and compression conditions are accurately achieved during construction.

Technical Summary

A ductile iron pipe joint achieves sealing through:

Elastic compression of a rubber gasket

Internal pressure-assisted sealing behavior

Flexible structural design that accommodates movement

This combination of elasticity, pressure response, and adaptability explains why ductile iron pipe joints are widely used in modern water infrastructure systems.

If you want to explore detailed specifications of various joint structures and connection methods, consult the comprehensive ductile iron pipe joint and connection section available on our website.

Previous: 6 Critical Checks During Ductile Iron Pipe Joint Installation

Next: No More

en

en  fra

fra  de

de  ru

ru  ara

ara  gle

gle  it

it  jp

jp  kor

kor  th

th  zh

zh