6 Critical Checks During Ductile Iron Pipe Joint Installation

2026-02-17 07:20:24 hits:0

Field Mistakes That Often Lead to Leakage

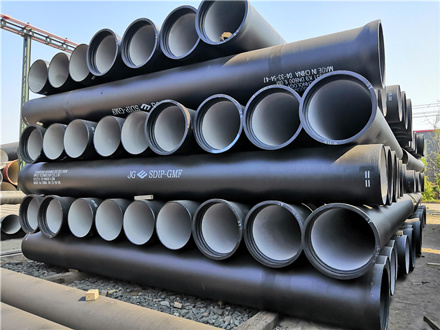

Reliable ductile iron pipeline performance depends heavily on correct joint installation.

In many projects, joint leakage is not caused by pipe defects, but by small procedural mistakes made on-site.

Before pressure testing or backfilling, construction teams should review several key installation points.

This guide highlights six practical checks that significantly improve joint reliability.

For detailed information on joint types and connection systems, visit:

👉 Ductile Iron Pipe Joints & Connections

1. Verify Rubber Gasket Seating Before Assembly

The sealing ring must sit evenly inside the socket groove.

Typical site problems include:

Gasket twisted during placement

Uneven seating inside the groove

Debris trapped behind the gasket

If the gasket is not properly positioned, sealing pressure becomes uneven once the pipe is pressurized.

Field tip:

Run a full visual and manual inspection around the entire circumference before inserting the spigot.

2. Ensure the Spigot Surface Is Completely Clean

The sealing performance depends on smooth contact between the spigot and gasket.

Common risks:

Sand or soil remaining on the pipe end

Rust flakes or coating damage

Lubricant applied over dirt

Contamination may scratch the gasket or reduce compression effectiveness.

Field tip:

Wipe the spigot and socket thoroughly before lubrication and assembly.

3. Confirm Full Insertion Depth

Each pipe has a marked insertion line that indicates the correct engagement position.

On-site errors occur when:

Workers stop pushing once resistance increases

The insertion mark is not checked

Misalignment prevents full engagement

Incomplete insertion reduces sealing reliability and may cause leakage during pressure testing.

Field tip:

Always confirm that the insertion mark aligns correctly after joint assembly.

4. Control Joint Deflection Within Allowable Limits

Push-on joints allow limited angular movement to accommodate minor alignment differences.

However, exceeding the designed deflection angle can:

Distort gasket compression

Increase stress on one side of the joint

Shorten long-term sealing life

Flexibility is a design allowance, not a solution for improper trench alignment.

Field tip:

Check manufacturer specifications for maximum allowable deflection based on pipe diameter.

5. Maintain Proper Support Under the Joint Area

Even correctly assembled joints may fail if bedding support is uneven.

Potential problems:

Void spaces beneath the joint

Inconsistent trench compaction

Differential soil settlement

When ground movement occurs, the joint becomes a stress concentration point.

Field tip:

Ensure uniform bedding support before backfilling and avoid leaving unsupported sections near joints.

6. Evaluate Axial Force Control Measures

In pressurized systems, axial thrust forces are generated at bends, tees, and changes in elevation.

If thrust control is insufficient:

The pipe may shift slightly over time

Sealing performance gradually decreases

Depending on system design, thrust blocks or restrained joints may be required.

Field tip:

Confirm that thrust resistance design matches pipeline pressure and layout conditions.

Key Takeaway for Construction Teams

Most joint issues can be prevented through systematic inspection during installation.

Reliable ductile iron pipe joint performance depends on:

Correct gasket placement

Clean assembly surfaces

Verified insertion depth

Controlled deflection

Stable bedding

Proper thrust management

Attention to these details during construction significantly reduces long-term leakage risk.

For more technical details about ductile iron pipe joint configurations, see:

👉 Ductile Iron Pipe Joints & Connections

en

en  fra

fra  de

de  ru

ru  ara

ara  gle

gle  it

it  jp

jp  kor

kor  th

th  zh

zh