Why Engineers Prefer 300mm DI Pipes for Reliable Water Networks

2025-11-07 17:23:14 hits:0

Introduction

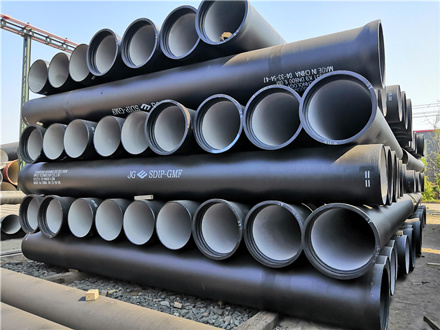

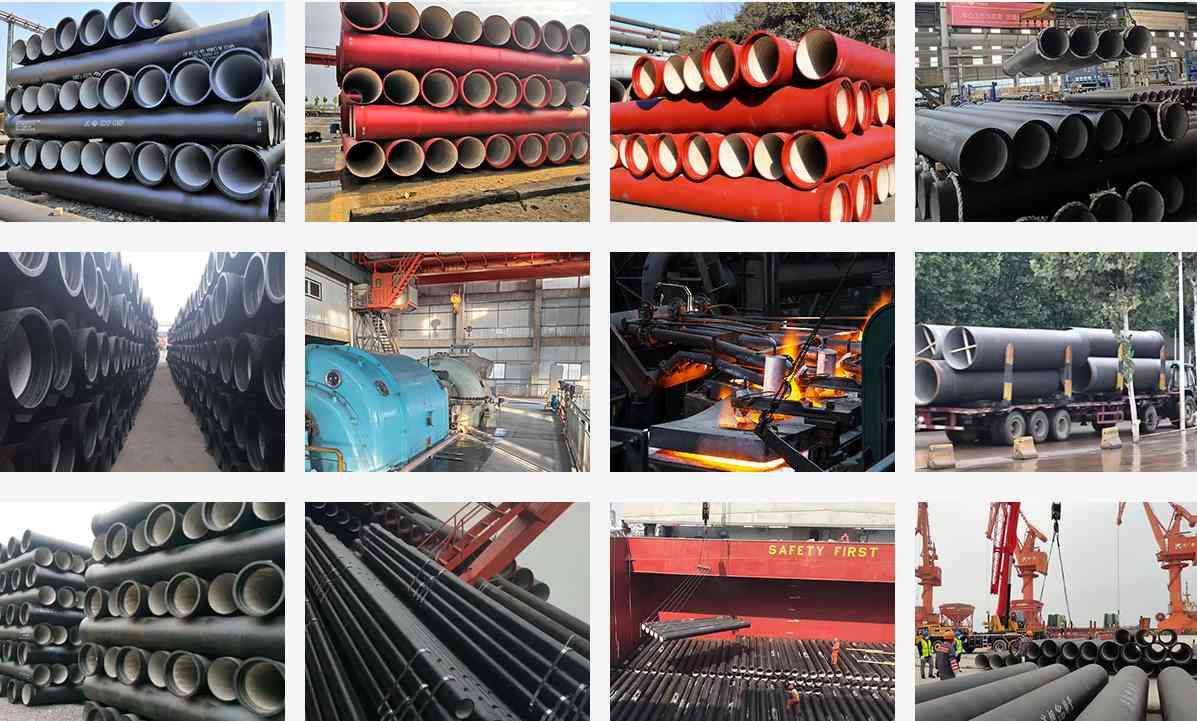

When designing or upgrading a water supply system, choosing the right pipe material is one of the most important decisions. Among many options—PVC, HDPE, steel, and concrete—ductile iron pipes (DI pipes) have become the most trusted solution for municipal and industrial projects.

In particular, the 300mm ductile iron pipe offers the ideal balance between strength, flexibility, and cost-effectiveness, making it one of the most popular diameters used in water distribution networks worldwide.

Understanding 300mm Ductile Iron Pipe

The term “300mm DI pipe” refers to a ductile iron pipeline with a nominal diameter of 300 millimeters.

These pipes are made from spheroidal graphite cast iron, which provides much higher tensile strength and impact resistance than traditional gray cast iron.

Most 300mm DI pipes conform to international standards such as:

ISO 2531 / EN 545: for potable water and pressure pipelines

AWWA C151: for ductile iron pipe systems in North America

Typical pressure classes include:

K7 – for low-pressure water distribution

K9 – for medium-pressure networks (most common)

K12 – for high-pressure or deep-buried systems

Each class determines the wall thickness and allowable working pressure, helping engineers select the best pipe according to project requirements.

Why 300mm Ductile Iron Pipe Is Ideal for Water Supply Systems

1. Superior Strength and Flexibility

Ductile iron has excellent mechanical properties—high tensile strength (≥420 MPa) and high yield strength (≥300 MPa).

This means a 300mm DI pipe can withstand both internal pressure and external ground load, making it suitable for all kinds of terrain, including rocky or unstable soils.

2. Excellent Corrosion Resistance

The internal surface is usually lined with cement mortar to protect against corrosion from water or soil chemicals.

The external coating—such as zinc + bitumen paint or epoxy—adds extra protection, ensuring long-term durability even in harsh environments.

3. Long Service Life

A properly installed 300mm ductile iron pipe can last over 50 years, requiring minimal maintenance. Compared to PVC or steel pipes, DI pipes provide the best life-cycle cost performance.

4. Reliable Hydraulic Performance

Smooth internal linings improve water flow and reduce head loss. The pipe’s rigidity and push-on joint system also minimize the risk of leakage, keeping the entire network efficient.

How to Select the Right Class and Pressure Rating

Choosing between K7, K9, or K12 depends mainly on your system’s pressure and installation conditions.

| Class | Typical Working Pressure | Recommended Application |

|---|---|---|

| K7 | ≤ 10 bar | Low-pressure rural supply, irrigation |

| K9 | ≤ 16 bar | Urban and industrial water networks |

| K12 | ≤ 25 bar | High-pressure pumping stations or mountainous areas |

Tips for selection:

For municipal water supply, 300mm K9 DI pipes are the most cost-effective and commonly used.

For long-distance or hilly projects, consider K12 for additional safety margin.

Always check compatibility with PN ratings and fitting materials.

Installation and Connection Tips

A major advantage of ductile iron pipes is their easy jointing system.

Push-on (spigot and socket) joint: Fast installation using rubber gaskets for watertight sealing.

Mechanical joint: Offers flexibility for maintenance and disassembly.

Flanged joint: Used in above-ground or plant piping connections.

When installing 300mm DI pipes:

Ensure proper gasket lubrication and alignment.

Follow the manufacturer’s burial depth and bedding material recommendations.

Test pressure after installation to confirm leak-tight performance.

These steps ensure a long-lasting and reliable water distribution line.

Where to Buy Reliable 300mm Ductile Iron Pipes

Selecting a trustworthy supplier is as important as selecting the right class.

Here’s what to look for when sourcing 300mm DI pipes:

Certified production: ISO 2531 / EN 545 / WRAS / SGS certificates

Testing reports: Tensile strength, hydraulic pressure, and coating inspection

Full accessories: Flanged fittings, gaskets, couplings, and valves

After-sales support: Technical guidance and export documentation

China has become one of the largest global producers of ductile iron pipes, providing competitive prices without compromising quality.

If you’re looking for a reliable manufacturer of 300mm ductile iron pipes, contact TIEGUE — we supply complete water pipeline solutions with guaranteed quality and fast delivery.

en

en  fra

fra  de

de  ru

ru  ara

ara  gle

gle  it

it  jp

jp  kor

kor  th

th  zh

zh