10 Steps to Manufacturing High-Quality Ductile Iron Pipes

2025-09-29 14:27:35 hits:0

Ductile iron pipes (DI pipes) are one of the most reliable materials for modern pipeline systems. With their high strength, toughness, and excellent corrosion resistance, they are widely used in municipal water supply, drainage, gas distribution, and industrial applications.

In this article, we’ll take a closer look at how ductile iron pipes are made, why the production process matters, and also introduce our company’s capabilities in producing pig iron, ductile iron pipes, and other castings.

Our Products and Production Capacity

Our company focuses on three main product categories: pig iron, ductile iron pipes, and various castings. Thanks to an integrated production system, we are able to ensure large-scale, stable supply for global customers.

Ironmaking System – Annual production of 1 million tons of foundry pig iron, steelmaking pig iron, and ductile iron pig iron.( Learn more about our pig iron products)

Pipe System – Annual production capacity of 800,000 tons of centrifugal ductile iron pipes, available in 26 specifications ranging from DN80 to DN2600. See ductile iron pipe details here

Supporting Products – We also provide mineral resources, pipe fittings, castings, and rubber gaskets, forming a complete supply chain from raw materials to finished products.

This combination of capacity and integration makes us a trusted partner for large-scale projects around the world.

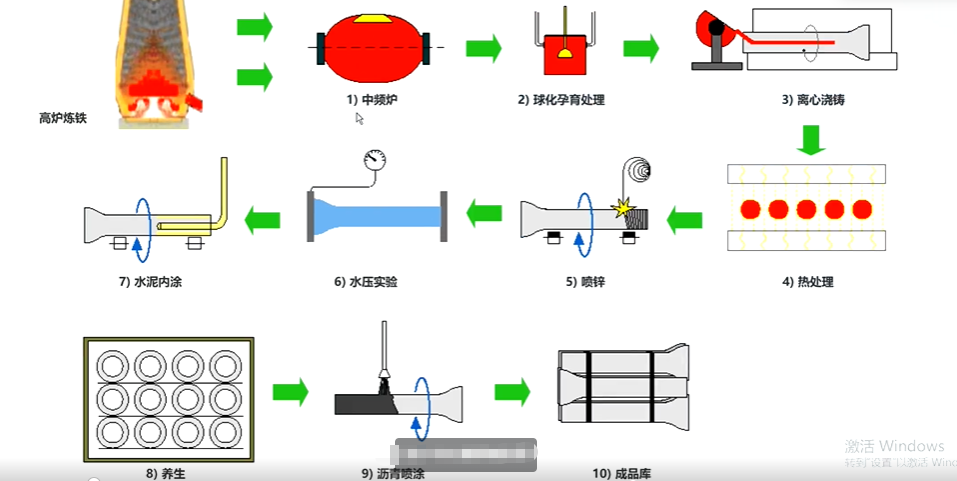

Step-by-Step Production Process of Ductile Iron Pipes

Producing ductile iron pipes is a highly controlled process. Each stage ensures that the final product has the strength and durability required for long-term use.

Melting – Pig iron, scrap steel, and additives are melted in medium-frequency furnaces to create molten iron with stable composition.

Nodulizing & Inoculation – Magnesium and rare earth alloys are added to improve graphite structure, giving the pipe its strength and toughness.

Centrifugal Casting – Molten iron is poured into rotating molds, producing pipes with uniform and dense walls.

Heat Treatment – Pipes are annealed or normalized to relieve internal stresses and enhance mechanical properties.

Zinc Coating – A protective zinc layer is sprayed on the outer surface for corrosion resistance.

Hydrostatic Testing – Every pipe undergoes pressure testing to guarantee leak-free performance.

Cement Mortar Lining – The inner wall is lined with cement mortar, protecting water quality and extending pipe life.

Curing – The lining is properly cured to achieve strength and durability.

Outer Coating – Asphalt or epoxy coatings provide an extra layer of corrosion protection.

Storage – Finished pipes are stored in a warehouse, ready for shipment worldwide.

Why This Matters

By understanding the production process, project managers and engineers can better evaluate the quality of ductile iron pipes they are sourcing. A well-controlled process means higher reliability, lower maintenance, and longer service life in the field.

With our million-ton annual capacity, strict quality control, and complete product range, we are confident in supporting infrastructure projects of all sizes.

Certifications and Quality Assurance

Quality and reliability are at the heart of our production. We are among the very few enterprises that have obtained the full ISO 7-system certifications, ensuring excellence in every aspect of management and production.

In addition, our products and services have passed multiple international certifications:

France 8V Quality Certification

After-Sales Service Certification

Swiss SGS Product Quality Certification

German TUV Product Certification

These certifications demonstrate not only our commitment to manufacturing excellence but also our dedication to customer satisfaction and long-term trust.

SAQ – Frequently Should-Ask Questions about Ductile Iron Pipes

Q1: What makes ductile iron pipes different from traditional cast iron pipes?

A: Ductile iron pipes are produced by adding magnesium to molten iron, which changes the graphite form into spherical nodules. This gives the pipes excellent toughness, flexibility, and impact resistance, while still maintaining high strength.

Q2: What sizes and specifications of ductile iron pipes do you offer?

A: Our production covers DN80 to DN2600 mm, with 26 specifications and multiple varieties. This allows us to meet a wide range of municipal, industrial, and infrastructure project needs.

Q3: How durable are ductile iron pipes in real applications?

A: With superior mechanical strength, corrosion resistance, and internal/external coatings, ductile iron pipes often have a service life of more than 100 years under normal operating conditions.

Q4: What international certifications ensure the quality of your pipes?

A: Our company is among the few in the industry certified with ISO’s seven major systems, French 8V quality certification, after-sales service certification, Swiss SGS product quality certification, and German TUV product certification.

Q5: Can you provide complete pipe system solutions, not just pipes?

A: Yes. Besides ductile iron pipes, we also provide fittings, castings, and rubber gaskets, ensuring a full pipeline solution for customers worldwide.

Q6: Which industries most commonly use ductile iron pipes?

A: Ductile iron pipes are widely used in urban water supply and drainage, power plants, gas distribution, agricultural irrigation, and various infrastructure projects due to their strength and reliability.

📩 Looking for a reliable supplier? Contact us here

en

en  fra

fra  de

de  ru

ru  ara

ara  gle

gle  it

it  jp

jp  kor

kor  th

th  zh

zh