A Must-Read for Foreign Trade Casting Imports and Exports: Analysis of PN and MPa Pressure Standards

2025-06-10 09:16:13 hits:0

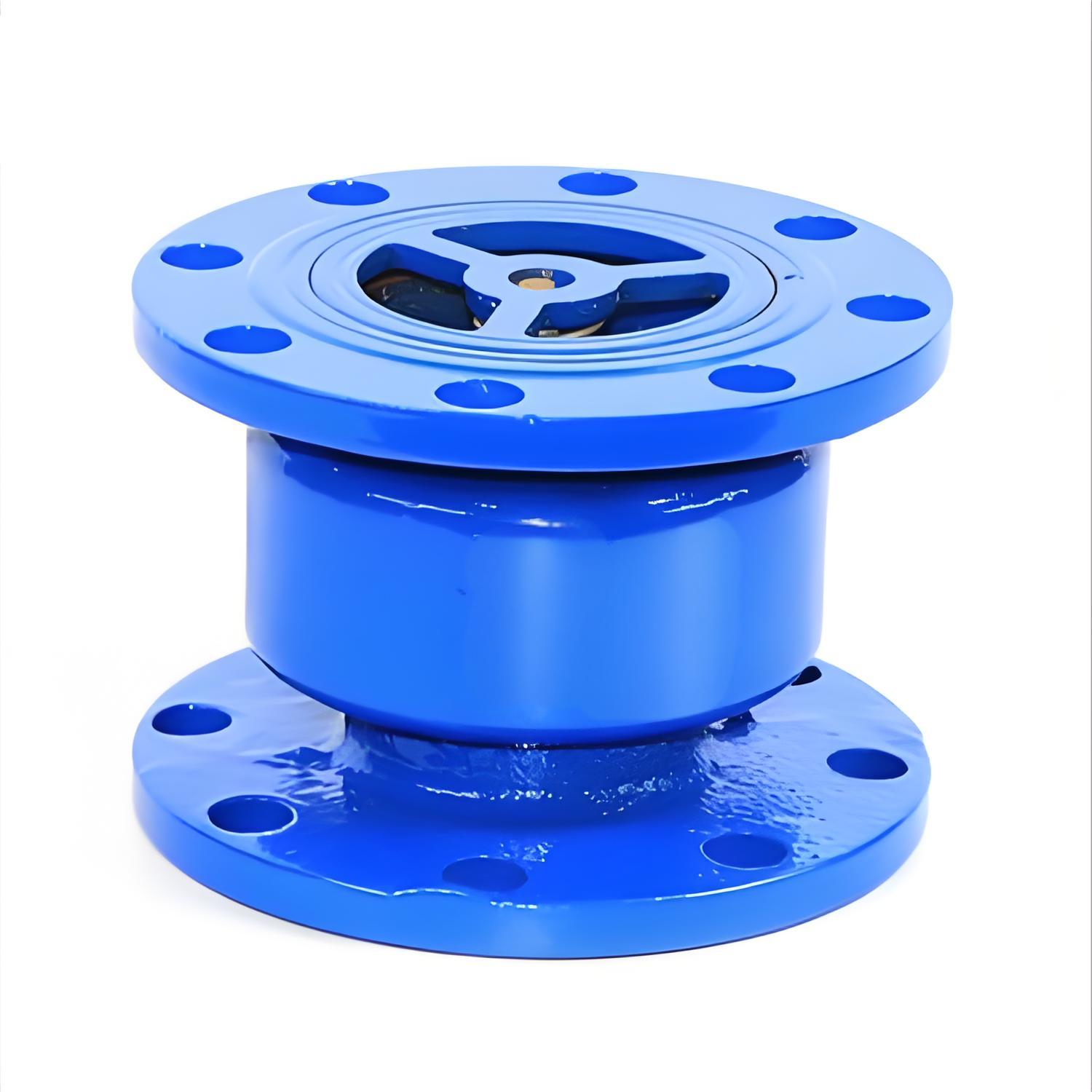

In the business of foreign trade casting exports, a precise grasp of the differences between PN (Nominal Pressure) and MPa (Megapascal) is crucial for avoiding selection risks of casting products such as flanges, valves, and pipes. This article analyzes the pressure systems of European standards (DIN - Deutsches Institut für Normung, EN - European Norm) and the International System of Units (SI, International System of Units), exploring their core applications in order communication, technical documentation, and compliant delivery. It aims to help foreign trade enterprises overcome standard barriers and enhance their international market competitiveness.

I. What is PN?

1. Definition: PN (Nominal Pressure) - The Grading "Symbol" of the European Standard System

PN (Nominal Pressure) is a symbol used in European standards (such as DIN and EN) to identify the pressure ratings of pipeline system components (pipes, valves, flanges, fittings, etc.). It represents the maximum allowable working pressure of these components at normal temperature (20°C).

2. Core Characteristics

PN is a pressure rating symbol, not a specific pressure value (e.g., PN16 ≠ 16MPa).

PN is temperature - sensitive: The pressure - bearing capacity of components decreases in high - temperature environments, requiring recalculation using material temperature - pressure tables. For detailed temperature - pressure calculation specifications, you can refer to the pressure standard documents on the official website of the European Committee for Standardization (CEN) [https://www.cen.eu/].

3. Common Ratings

Common ratings like PN6, PN10, PN16, PN25, and PN40 are widely applied in casting products compliant with European standards (GB/T, DIN). Our company's [valve product page] features valves with multiple common PN ratings, suitable for various industrial and engineering applications.

Application Scenarios of PN

PN helps quickly match customers' requirements for the pressure ratings of casting products. For instance, when a customer requests "PN25 valves", it is essential to clarify that they can withstand 25 bar (approximately 2.5 MPa) at normal temperature.

II. What is MPa (Megapascal)?

1. Definition

MPa is a unit of pressure in the International System of Units (SI), directly indicating the actual pressure value. It is applicable throughout the processes of design, testing, and technical parameter description.

In the product introduction of our company's ductile iron pipes, pressure parameters are all marked in MPa to ensure accurate data transmission. You can contact us to obtain detailed PDF materials about ductile iron pipes and their fittings.

2. Core Characteristics

As a physical unit, MPa directly represents pressure magnitude (1 MPa = 10⁶ Pa = 10 bar ≈ 145 psi).

MPa is temperature - independent, enabling consistent measurement across different environments (e.g., design pressure under high - temperature conditions is still expressed in MPa).

MPa is a globally universal unit without regional limitations, serving as a core parameter in technical documents and business contracts.

3. Application Scenarios

MPa precisely conveys technical requirements. For example, the test pressure of ductile iron pipes marked as "1.6 MPa" directly corresponds to an actual test pressure of 16 bar.

III. What are the Differences between PN and MPa?

Comparison Items | PN (Nominal Pressure - Grading Symbol in European Casting Standards) | MPa (Megapascal - International Pressure Unit) |

Nature | Pressure rating symbol | Pressure unit |

Application Scenarios | Identifies the pressure ratings of flanges, valves, etc. | Represents actual values of design/test pressures |

Temperature Correlation | Only applicable at normal temperature (20°C); derating for high temps | Unaffected by temperature |

Conversion Relationship | 1PN ≈ 0.1MPa (e.g., PN16 ≈ 1.6MPa) | 1MPa = 10bar = 145psi |

Standard System | European standards (GB/T, DIN, etc.) | Internationally universal (no regional restrictions) |

IV. Practical Cases in Foreign Trade Castings: PN and MPa in Order Communication & Product Selection

1. Order Communication: Accurately Identifying Customer Requirements

For European and Euro - standard regions: Customers often use PN ratings (e.g., "PN40 flanges"). Key info to confirm:

Medium temperature: If higher than normal, advise adjusting PN via temperature - pressure tables (e.g., PN25 flange at 100°C may only allow 1.8MPa; upgrade to PN40 for 2.5MPa actual pressure).

Differentiation from ASME Class/JIS K: Avoid confusion (e.g., Class 150 ≈ PN20, 10K ≈ PN16). Learn more about ASME pressure standards [https://www.asme.org/].

For other regions: When customers specify MPa (e.g., "2.0MPa design pressure"), convert to PN (2.0MPa ≈ PN20) and confirm Euro - standard acceptance.

2. Product Selection: Avoiding Temperature & Unit Pitfalls

Case 1: Flange Selection (High - Temp Error)

Wrong: Directly matching PN25 for 2.5MPa@80°C.

Correct:

Check flange temperature - pressure table: PN25 allows 2.0MPa at 80°C.

Recommend PN40 (4.0MPa at normal temp, suitable for high - temp after calculation).Result: Avoided a potential pipeline failure and secured long - term client trust.

Case 2: Valve Technical ComplianceSpecify both PN and MPa: "Valve PN16, design pressure 1.6MPa, test pressure 2.4MPa" ensures clear communication.

3. Document Compliance: Contracts & Technical Files

Contracts: Define standards clearly, e.g., "All flanges comply with EN 1092 - 1, PN16 (1.6MPa)".

Technical Files:

Mark "PN16 = 1.6MPa" on drawings.

Provide high - temp derating data (e.g., "PN25 allows 1.5MPa at 150°C") in material reports. Access all reports on our [quality inspection page].

V. PN And MPa -Common Misconceptions and Countermeasures

1. Misconception: PN Values = MPa Values

Error: Assuming PN16 = 16MPa (actual: 1.6MPa).

Fix: Create a "PN - MPa conversion table" and train teams (e.g., PN6 = 0.6MPa, PN10 = 1.0MPa).

2. Ignoring Temperature Effects on PN

Error: Supplying PN25 for high - temp without derating, leading to component failure.

Fix:

Mandate temperature data from clients; default to high - temp calculations.

Develop material temperature - pressure charts (e.g., carbon steel/stainless steel derating coefficients).

3. Confusing PN with Class/K Grade

Error: Class 150 = PN16 (actual: Class 150 ≈ PN20).

Fix:

Memorize conversions: Class 150 ≈ PN20, 20K ≈ PN40.

For non - Euro standards, offer direct - rated products (e.g., Class 150 flanges) or clarify conversions.

VI. Synergy with International Standards

1. ASME Class System Adaptation

Class 150 ≈ PN20 (2.0MPa) for water/steam.

Class 300 ≈ PN50 (5.0MPa) for high - pressure.

Tip: Label "Class 150/PN20" for US exports to enhance compatibility.

2. JIS K Grade Integration

10K ≈ PN16 (1.6MPa) for water pipes.

20K ≈ PN40 (4.0MPa) for industrial use.

Tip: Use "20K ball valves" for Japan, with PN notes in technical docs.

VII. Conclusion

PN (pressure rating symbol) for quick selection; MPa (unit) for precision calculations.

Key formula: 1PN ≈ 0.1MPa (e.g., PN16 ≈ 1.6MPa).

Critical: Always derate PN for high temperatures!

Mastering these differences eliminates selection errors and safety risks. Contact us today for professional pressure standard solutions or casting procurement. Click [Get a Quote](link to contact page) to start your project with confidence!

en

en  fra

fra  de

de  ru

ru  ara

ara  gle

gle  it

it  jp

jp  kor

kor  th

th  zh

zh