Ductile Iron Pipe Installation Guide: Stacking and Storage - A Key Step in Safeguarding Pipe Quality

2025-06-04 13:39:15 hits:0

Ductile Iron Pipe Installation Guide: Stacking and Storage - A Key Step in Safeguarding Pipe Quality

As a series dedicated to sharing ductile iron pipe supply and installation expertise, our previous article focused on lifting procedures. Today, we delve into stacking and storage—a crucial but frequently neglected aspect that protects ductile iron pipe quality and ensures smooth subsequent installation. Improper handling can lead to pipe deformation, anti - corrosion coating damage, and even compromised gasket sealing performance. Leveraging years of supply experience, we break down the core principles of stacking and storage to help you control project quality from the ground up.+

I. Pipe Stacking: Optimize Site Selection and Methods to Avoid Damage

(A) Foundational Requirements: Site Preparation

For ductile iron pipe construction safety and efficiency, prioritize flat, firm ground for stacking. Avoid inclined areas or areas with hard objects (e.g., gravel, rebar)—slopes can cause pipes to roll, while sharp objects may puncture anti - corrosion layers and scratch pipe ends. Additionally, ensure spigots and sockets are staggered during stacking to prevent direct contact between spigot ends and socket necks, which could damage connections.

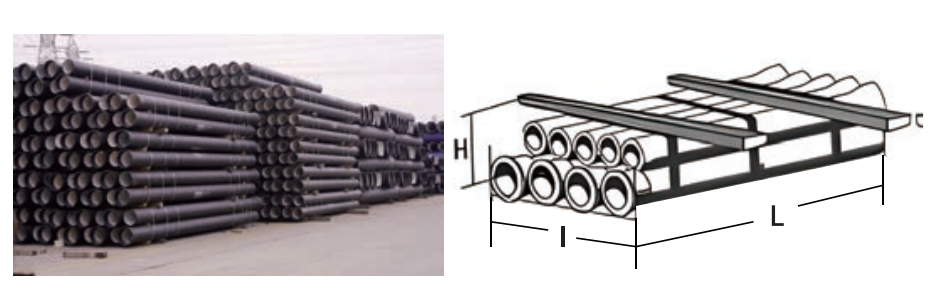

Stacking methods vary between warehouses and construction sites. Common approaches include well - shaped stacking, linear stacking, and pyramid - style stacking. Choose the method that best suits your needs.

(B) Packed Pipe Stacking (DN80–DN300)

For bundled ductile iron pipes, use methods such as well - shaped stacking based on specifications. Strictly adhere to layer limits (refer to the table below). For example, DN80–DN100 pipes can be stacked up to 6 layers, while paying attention to bundle dimensions (length × width × height) to ensure stability and prevent deformation.

Recommended Stacking Parameters for Bundled Pipes:

| DN Size | Layers | Bundle Dimensions (Layers × Pipes per Layer / Length L / Width W / Height H) |

|---|---|---|

| DN80 | 6 | 5×3 / 6.205m / 0.544m / 0.434m |

| DN100 | 6 | 5×3 / 6.246m / 0.644m / 0.515m |

| DN150 | 6 | 3×3 / 6.258m / 0.558m / 0.651m |

| DN200 | 6 | 3×2 / 6.270m / 0.719m / 0.567m |

| DN250 | 5 | 2×2 / 6.280m / 0.598m / 0.668m |

| DN300 | 5 | 2×2 / 6.290m / 0.706m / 0.775m |

(C) Unpacked Pipe Stacking (DN350–DN2200)

For large - diameter single pipes, three stacking methods are recommended:

Pyramid - Style Stacking:

Suitable for long - term storage (e.g., DN700 stacked in 5 layers, DN1000 in 4 layers). The layers are gradually narrowed to distribute pressure evenly.

Linear Stacking:

Ideal for short - term storage or spacious sites. Control layer counts to avoid uneven stress at pipe ends.

Well - Shaped Stacking:

Enhances stability through crisscrossed layers.

Example: DN200 pipes stacked in 12 layers with 23/22 pipes per layer.

Layer Recommendations for Large - Diameter Pipes:

| DN Size | Pyramid Layers | Linear Layers | Well - Shaped Stacking (Layers / Pipes per Layer) |

|---|---|---|---|

| DN80 | - | 18 | - |

| DN100 | 38 | 15 | - |

| DN150 | 26 | 12 | - |

| DN200 | 20 | 12 | 12 layers, 23/22 pipes |

| DN250 | 16 | 10 | 12 layers, 18 pipes |

| DN300 | 13 | 9 | 9 layers, 15 pipes |

| DN350 | 11 | 9 | 11 layers, 12 pipes |

| DN400 | 9 | 9 | 10 layers, 12 pipes |

| DN450 | 9 | - | 9 layers, 12 pipes |

| DN500 | 8 | 6 | 8 layers, 9 pipes |

| DN600 | 7 | 6 | 6 layers, 9 pipes |

| DN700 | 5 | - | 5 layers, 8 pipes |

| DN800 | 5 | - | 4 layers, 7 pipes |

| DN900 | 4 | - | 3 layers, 6 pipes |

| DN1000 | 4 | - | 2 layers, 6 pipes |

| DN1200+ | 3–1 | - | - |

II. Gasket Storage: Preserve Sealing Performance

Gaskets are critical for ductile iron pipe joint sealing. Improper storage accelerates aging and deformation, directly impacting post - installation leak resistance.

(A) Storage Method: Light - Proof + Original Packaging

Unused Gaskets: It is recommended that they be kept in original unopened packaging. Store ductile iron pipe gaskets in a cool, dry warehouse away from heat sources (e.g., welding equipment, boilers) and chemicals (e.g., solvents, acids).

Light Exposure: Avoid direct sunlight or artificial strong light, which degrade rubber elasticity and sealing properties.

(B) Shelf Life: Monitor Duration to Prevent Decay

Under standard storage, gaskets retain performance for 5 years from production. For gaskets that exceed this period, conduct sampling tests (e.g., tensile strength, sealing performance) before use. Minimize inventory and procure based on demand to reduce aging risks.

III. Safety Precautions: Avoid Stacking Hazards

Anti - Rolling Measures: Place triangular wood or flexible stoppers next to bottom - layer pipes to prevent sliding.

Restricted Zones: Prohibit personnel from walking or placing equipment near pipe stacks, since collapses risk injury or equipment damage. Clearly mark danger zones.

Conclusion

Stacking and storage are foundational to maintaining ductile iron pipe quality from production to installation. Adhering to site, stacking, and gasket storage protocols prevents material damage and ensures joint sealing integrity. In our next guide, we’ll explore ductile iron pipe cutting techniques—beveling, chamfering, and rounding. Stay tuned for more professional insights!

Previous Articles:

About Us:

Tiegu, as a global supplier of ductile iron pipes, provides high - quality products and solutions for municipal engineering, water conservancy, and industrial pipelines. With a full range of specifications, an expert technical team, and a comprehensive logistics network, we ensure every pipe meets international standards. From storage support to installation guidance, we prioritize client success.

Contact Us Now for Quotes and Expert Assistance:

View the list of ductile iron pipe products

Keywords: Ductile iron pipe stacking, material storage, gasket preservation, installation safety, quality control.

Optimize your projects with scientific stacking and storage—protecting pipe quality and controlling costs from day one. Let’s continue this journey toward flawless installations!

en

en  fra

fra  de

de  ru

ru  ara

ara  gle

gle  it

it  jp

jp  kor

kor  th

th  zh

zh