Pig Iron Supply for Foundries | Consistent Quality, 1.2M+ Tons Annually – Tiegu

2026-01-23 15:27:19 hits:0

A direct question for foundry managers:

Have you experienced scrap losses this year due to unstable pig iron quality?

In discussions with ductile iron foundries serving machinery, valve, automotive, and infrastructure projects, the same concern comes up repeatedly:

“Even a small deviation in sulfur or phosphorus can ruin an entire batch of castings. The real problem isn’t just the loss — it’s not knowing who will take responsibility when it happens.”

This issue is not region-specific.

Across global foundry operations, pig iron sourcing remains one of the most underestimated production risks.

After years of working with casting plants and pig iron suppliers, one conclusion is clear:

👉 Choosing a pig iron supplier is less about technical claims and more about reliability, consistency, and accountability.

1. Three Common Procurement Assumptions That Cause Foundry Losses

Before asking “Who has the best technology?”, foundries should ask “Who can be relied on long term?”

Most sourcing problems stem from the following assumptions.

Mistake #1: “Pig iron is a commodity — lower price is enough”

A medium-sized industrial foundry once purchased pig iron at a price noticeably below the market average.

What followed:

Silicon content fluctuated beyond process tolerance

Mechanical properties became inconsistent

A full batch of castings failed inspection

Investigation later showed the supplier had mixed pig iron from multiple furnaces, with no unified composition control.

📌 Key takeaway: Pig iron may look like a commodity, but inconsistency quickly turns into high scrap and rework costs.

Mistake #2: “If supply was stable before, it will stay stable”

Many foundries experience a similar pattern:

Smooth deliveries during off-peak periods

Sudden shortages during peak production seasons

No guaranteed allocation when ironworks reduce output

Even short interruptions can:

Halt melting operations

Increase labor and energy losses

Delay customer shipments

📌 Key takeaway: Past performance does not guarantee future supply security.

Mistake #3: “Quality disputes are unavoidable — suppliers won’t take responsibility”

When chemical composition exceeds agreed limits:

Traders shift responsibility to ironworks

Ironworks shift responsibility back to traders

Foundries absorb the loss

📌 Key takeaway: Without clear contractual responsibility, quality risks always fall on the foundry.

2. What Really Matters: Three Criteria Beyond Marketing Claims

Foundries don’t need theoretical performance promises.

They need stable composition, predictable supply, and clear accountability.

Based on the practices of large-scale service-oriented suppliers such as Tiegu, these criteria consistently separate reliable suppliers from risky ones.

1️⃣ Source Transparency: Trader or Direct Mill Procurement?

Typical traders

Purchase from multiple sources

Limited batch traceability

Little authority when problems arise

Tiegu’s approach

Direct strategic cooperation with large-scale pig iron producers

Material loaded directly from blast furnace systems

Every shipment includes:

Furnace number

Chemical analysis report

Batch traceability documentation

📌 This enables foundries to maintain consistent melting performance across production batches.

2️⃣ After-Sales Accountability: Who Takes Responsibility?

Many suppliers offer verbal assurances, but few formalize responsibility.

Tiegu provides:

Written quality clauses in supply contracts

Replacement or return for composition deviation

Coverage of testing and verification costs

This approach helps customers:

Resume production quickly

Avoid prolonged disputes

Protect their own delivery commitments

📌 Accountability only works when it is written, measurable, and enforceable.

3️⃣ Supply Capacity: Can the Supplier Perform Under Pressure?

Small-volume suppliers often struggle when:

Ironworks prioritize large customers

Output is restricted during peak demand

Tiegu’s scale advantage

Annual pig iron supply exceeding 1.2 million tons

Long-term cooperation with ironworks producing over 3 million tons annually

Reserved supply allocations for long-term customers

📌 Scale directly translates into supply reliability.

3. Supplier Comparison: Where Most Options Fall Short

Supplier Type | Common Limitations | Tiegu’s Advantage |

General traders | Weak source control, poor traceability | Direct mill sourcing, batch documentation |

Small agents | Limited supply during peak season | Reserved capacity with large producers |

Regional suppliers | Narrow logistics coverage | Multi-location storage and flexible delivery |

Tiegu operates multiple regional storage and distribution hubs, allowing:

Faster delivery to major foundry clusters

Reduced logistics risk

Flexible response to urgent demand

4. A Practical Three-Step Checklist for Foundry Procurement Teams

Step 1: Verify Supplier Fundamentals

Transparent sourcing model

Stable partnerships with large ironworks

Clear quality documentation

Step 2: Review Recent Data, Not Old Samples

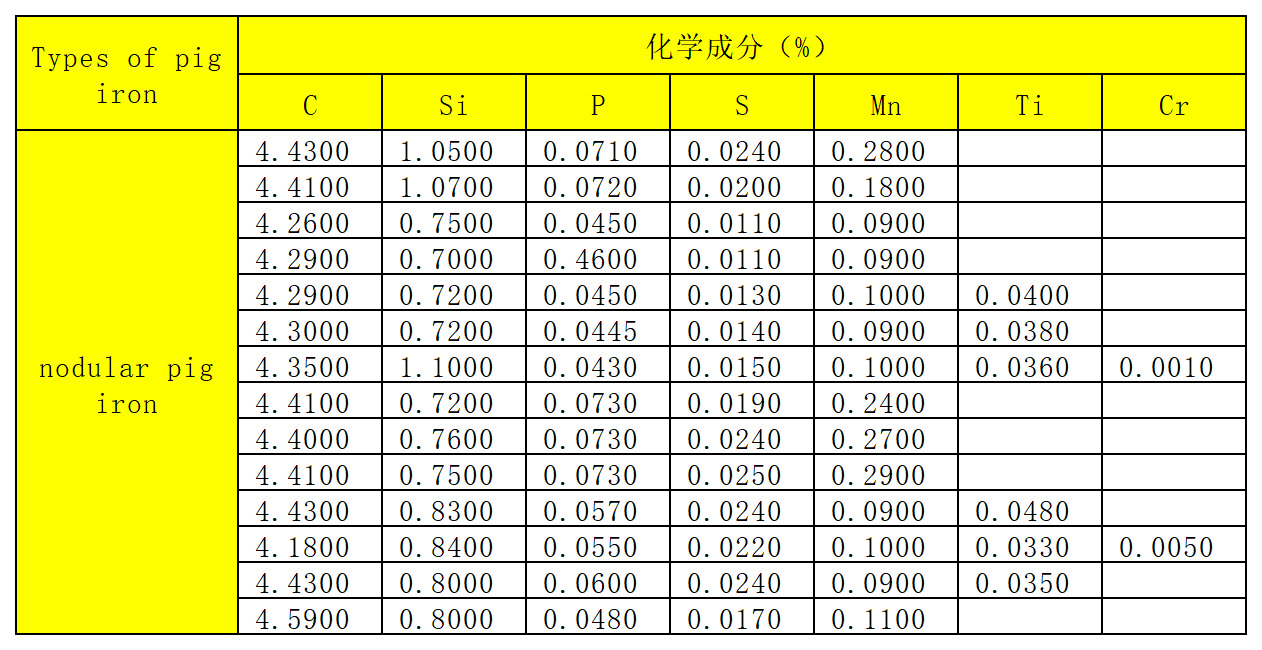

Request recent chemical analysis reports

Review composition fluctuation ranges

Avoid suppliers unwilling to share batch data

Step 3: Confirm Responsibility Before Negotiating Price

Ask directly:

What happens if composition exceeds limits?

Is replacement or compensation contractually guaranteed?

A slightly higher unit price is often far cheaper than a major scrap incident.

5. Final Thought: Reliability Is the Real Competitive Advantage

Foundry margins are thin worldwide.

Every unstable ton of pig iron increases hidden production costs.

The real value of suppliers like Tiegu lies in:

Consistent quality

Predictable supply

Clear responsibility when issues arise

In recent years, Tiegu’s pig iron supply volume has increased from approximately 900,000 tons to over 1.2 million tons annually, reflecting a simple reality:

📈 Foundries continue working with suppliers who reduce risk — not just price.

If your foundry is reviewing pig iron sourcing options, comparing your current supplier against these criteria is a practical first step.

Final takeaway:

Half of a foundry’s profit is created on the shop floor.

The other half is decided before raw materials arrive.

Previous: Comprehensive Ductile Iron Pipe Engineering Solutions

Next: No More

en

en  fra

fra  de

de  ru

ru  ara

ara  gle

gle  it

it  jp

jp  kor

kor  th

th  zh

zh