Why Ductile Iron Pipe Is Ideal for Sanitary Sewer Systems

2025-10-23 17:38:46 hits:0

1. Introduction

In modern urban infrastructure, sanitary sewer systems are critical for safely transporting wastewater and protecting public health.

Choosing the right pipe material directly impacts system longevity, maintenance costs, and environmental safety.

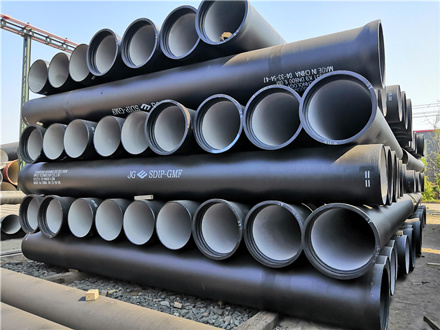

Among the many available options, ductile iron pipe (DIP) has become the preferred solution in numerous municipal and industrial sewer projects due to its superior mechanical strength, corrosion resistance, and long service life.

2. Characteristics of Sanitary Sewer Systems

Sanitary sewer pipelines are typically installed underground and operate under continuous exposure to corrosive conditions caused by wastewater, hydrogen sulfide gas (H₂S), and fluctuating flow pressures.

Key challenges include:

Corrosion from acidic or sulfur-containing gases

Soil movement and heavy loads from traffic or construction

Abrasion from sediment in the wastewater

Leakage prevention, ensuring environmental protection

Therefore, a reliable pipeline material must have excellent mechanical performance, resistance to chemical attack, and tight joint sealing capability.

3. Advantages of Ductile Iron Pipe in Sewer Applications

(1) High Mechanical Strength

Ductile iron pipe combines the strength of steel with the durability of cast iron.

It withstands heavy soil loads, ground movement, and external pressure—making it especially suitable for deep burial or heavy-traffic areas.

(2) Excellent Corrosion Resistance

With cement mortar lining, epoxy coating, or polyethylene sleeve protection, ductile iron pipe resists internal chemical attack and external soil corrosion, even in harsh wastewater environments.

(3) Leak-Proof Joint System

Push-on and mechanical joints ensure excellent sealing performance.

This prevents wastewater leakage, protecting soil and groundwater from contamination.

(4) Long Service Life & Low Maintenance

Properly installed ductile iron pipelines can last over 50 years, significantly reducing maintenance and replacement costs compared with PVC or concrete pipes.

(5) Ease of Installation

Despite its strength, DIP offers good flexibility and easy installation.

It can accommodate small ground settlements and can be cut or connected quickly on site, improving project efficiency.

4. Common Coating and Lining Types

| Coating/Lining Type | Function | Application |

|---|---|---|

| Cement Mortar Lining (CML) | Protects against internal corrosion caused by sewage | Most common lining for sanitary sewers |

| Epoxy or Fusion-Bonded Coating | Enhances external corrosion resistance | Suitable for aggressive soil conditions |

| Bituminous Coating | Provides basic external protection | Standard coating option |

| Polyethylene Sleeve (PE Wrap) | Additional corrosion barrier | Used in highly corrosive environments |

5. Comparison with Other Pipe Materials

| Property | Ductile Iron Pipe | PVC Pipe | Concrete Pipe |

|---|---|---|---|

| Strength | Very high | Low | Medium |

| Corrosion Resistance | Excellent (with lining) | Moderate | Poor |

| Service Life | 50+ years | 20–30 years | 25–40 years |

| Leakage Resistance | Excellent | Good | Moderate |

| Maintenance Cost | Low | Moderate | High |

| Installation Difficulty | Moderate | Easy | Difficult |

➡️ Overall, ductile iron pipe provides the best balance of strength, longevity, and corrosion protection among all major materials used in sewer construction.

6. Real-World Applications

Municipal wastewater systems in China, the Middle East, and Europe

Industrial wastewater discharge pipelines

Underground drainage networks in coastal or soft-soil regions

Case studies show that even after decades of operation, ductile iron pipes remain structurally sound and corrosion-free when properly lined and installed.

7. Conclusion

In sanitary sewer systems that demand high strength, corrosion resistance, and long service life, ductile iron pipe (DIP) stands out as the best choice.

It performs reliably even under harsh underground conditions, helping reduce lifecycle costs and ensuring long-term operational stability.

Whether for new infrastructure projects or sewer rehabilitation, ductile iron pipes offer the perfect balance between engineering performance and economic efficiency, making them an ideal solution for sustainable wastewater systems.

📞 Contact Tiegu

If you are looking for a reliable ductile iron pipe supplier or wish to learn more about sanitary sewer pipeline solutions,

feel free to reach out to the Tiegu professional team. We provide:

A full range of ductile iron pipes and fittings

Optional cement, epoxy, or internal lining solutions

Products meeting international standards (ISO 2531 / EN 545 / AWWA C151)

One-stop export and logistics support

Tiegu — Connecting Global Sewer Systems with Quality Made in China.

en

en  fra

fra  de

de  ru

ru  ara

ara  gle

gle  it

it  jp

jp  kor

kor  th

th  zh

zh