10 Production of ductile iron pipe– How Tiegu Ensures Strength and Quality

2025-10-13 11:25:21 hits:0

Introduction

Ductile iron pipes (DI pipes) are known for their exceptional strength, corrosion resistance, and long service life. At Tiegu, we manufacture high-quality ductile iron pipes through a precise and standardized production process that ensures both mechanical performance and reliability.

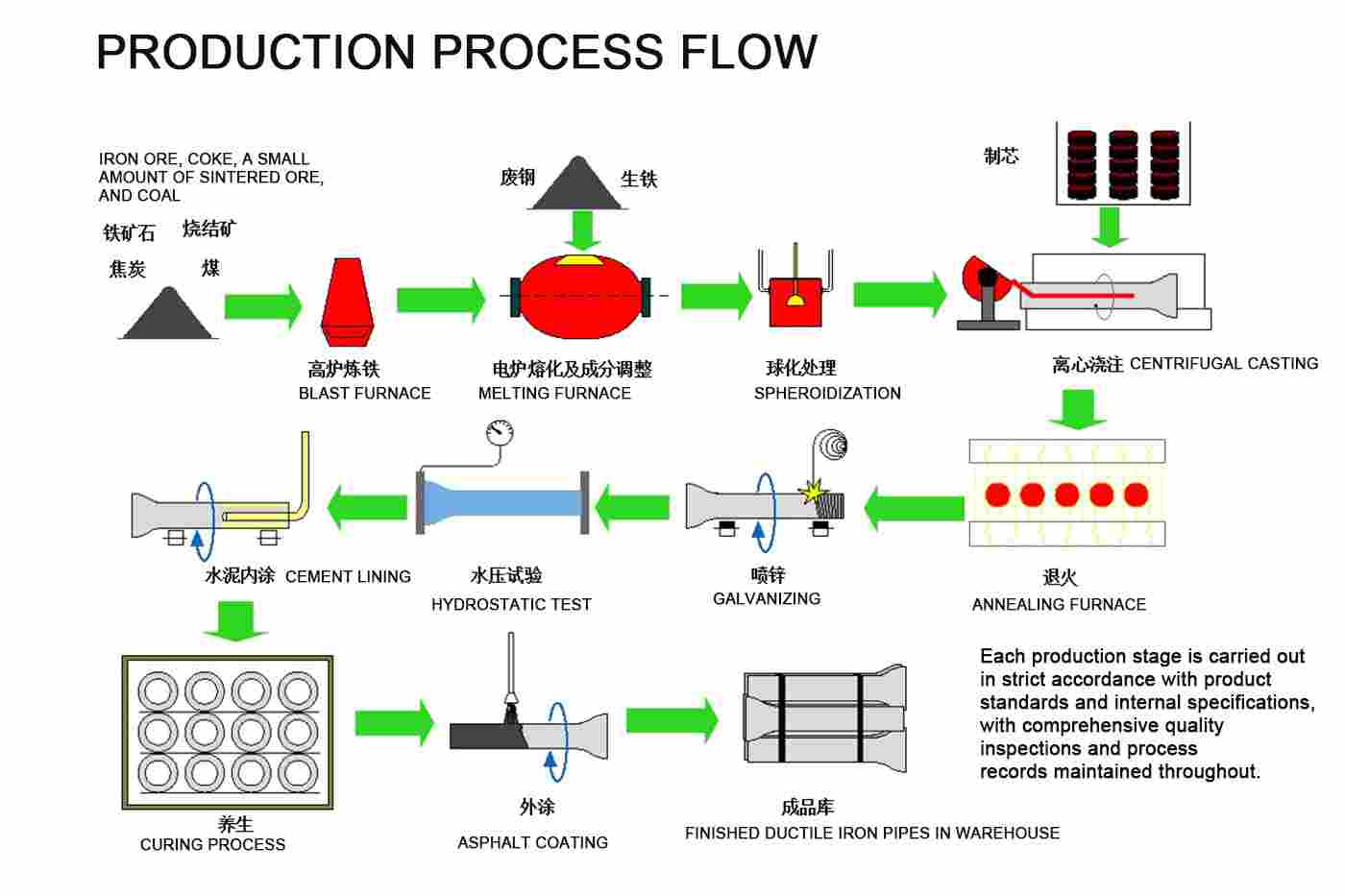

Below is a step-by-step explanation of the Tiegu ductile iron pipe manufacturing process, from raw material melting to final inspection and coating.

1. Blast Furnace Ironmaking

The process begins in the blast furnace, where raw materials such as iron ore, coke, and limestone are smelted to produce hot metal (pig iron). This molten iron forms the base for ductile iron production, with controlled composition and high purity.

2. Melting in Medium-Frequency Furnace

The hot metal is then transferred to a medium-frequency induction furnace, where it is remelted and adjusted to the ideal chemical composition.

Alloying elements such as carbon, silicon, and manganese are added to ensure the molten iron reaches the required quality for ductile iron casting.

3. Spheroidization and Inoculation Treatment

This is the core step in ductile iron production. Magnesium (Mg) and other additives are introduced into the molten iron in a controlled environment.

This process transforms the graphite into spherical nodules, improving ductility and impact resistance.

After that, inoculation treatment further enhances the uniformity and structure of the metal.

4. Centrifugal Casting

The treated molten iron is poured into a rotating steel mold using centrifugal casting machines.

Under high-speed rotation, the metal is evenly distributed along the mold wall, forming a dense and defect-free pipe body.

Centrifugal casting ensures uniform wall thickness and excellent mechanical properties.

5. Heat Treatment

After casting, pipes are transferred to a gas-fired annealing furnace and reheated to around 900–930°C.

This heat treatment (annealing) relieves internal stresses, enhances toughness, and stabilizes the microstructure of the ductile iron.

Controlled cooling ensures the pipes maintain dimensional accuracy and strength.

6. Galvanizing and Surface Protection

To enhance corrosion resistance, Tiegu applies a zinc (galvanized) coating on the pipe’s outer surface.

This protective layer prevents oxidation and extends the pipe’s service life, especially in underground or humid environments.

7. Hydrostatic Pressure Testing

Every pipe undergoes a hydrostatic pressure test to verify its structural integrity and leak-proof performance.

Only pipes that pass this test are approved for the next stage.

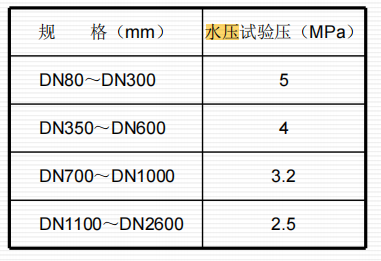

Every ductile iron pipe produced by our company must undergo a hydrostatic pressure test in strict accordance with the standard.

Each pipe is tested to check for any leakage under the specified pressure and holding time.

Different pipe sizes are tested at different pressure levels.

Pipes that pass the test without leakage proceed to the next production stage, while those that fail are isolated and returned to the melting process for remelting.

8. Cement Mortar Lining

A cement mortar lining is applied to the inner wall of the pipe.

The pipe is then spun to achieve a smooth and uniform lining surface.

This lining provides excellent protection against corrosion and improves water flow efficiency.

9. Curing Process

After lining, pipes enter a curing chamber for controlled drying and hardening of the cement.

Proper curing ensures long-term durability and prevents cracking or delamination.

10. Asphalt Coating and Final Finishing

The external surface is sprayed with asphalt paint as an additional anti-corrosion layer.

After final inspection and marking, the finished pipes are sent to the product warehouse ready for delivery.

Conclusion

The Tiegu ductile iron pipe manufacturing process combines advanced metallurgical control, precision casting, and multiple protective treatments to produce durable, leak-proof, and corrosion-resistant pipes.

Whether for water supply, drainage, or industrial applications, Tiegu’s ductile iron pipes meet international standards such as ISO 2531, EN 545, and AWWA C151.

For high-quality ductile iron pipes and fittings, contact Tiegu — your trusted supplier and partner in global infrastructure solutions.

en

en  fra

fra  de

de  ru

ru  ara

ara  gle

gle  it

it  jp

jp  kor

kor  th

th  zh

zh