Cast Iron Materials for Automobile Engine Blocks

Are you in search of high-quality cast iron materials for automotive engine blocks? Tiegu is your trusted supplier. Our offerings, such as HT250 gray iron and QT500-7 ductile iron, meet stringent international standards, boasting excellent castability, mechanical strength, and cost-efficiency. Contact Tiegu today! Phone: +86 152 5613 5588 Email: zbw@tiegu.net

Introduction

I. Current Usage Status of Pig Iron in Automobile Engine Blocks

(I) Influence of Pig Iron Elements on Engine Blocks

The proportion of elements in pig iron directly determines the performance of engine blocks.

Carbon (C), the main component, ranges from 2.11% to 4.3%. When present as graphite, it enhances molten iron fluidity for casting complex structures, though excessive carbon reduces material strength.

Silicon (Si) promotes graphitization, reduces white - mouth tendency, and improves toughness/machinability while aiding heat dissipation.

Manganese (Mn) neutralizes sulfur (forming MnS) to enhance strength and wear resistance.

Harmful elements like sulfur (reducing fluidity and causing hot cracking) and phosphorus (brittleness) must be strictly controlled (typically ≤ 0.08%).

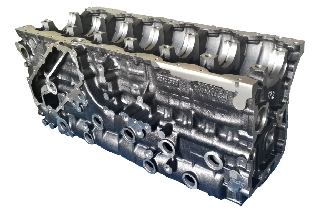

(II) Current Application of Gray Iron and Ductile Iron in Engine Blocks

Gray iron and ductile iron remain the dominant materials in engine block manufacturing. Gray iron, with excellent castability, machinability, and cost - efficiency, accounts for over 60% of mid - to low - end vehicle applications.

Ductile iron, valued for higher strength and toughness, has seen its market share rise to ~30% in high - performance/large - horsepower engines and lightweight designs, with the remainder occupied by aluminum alloys.

II. Gray Iron for Engine Blocks

(I) Advantages

Excellent Castability: Molten gray iron flows readily to fill complex molds, minimizing casting defects and enabling precise formation of internal channels (e.g., water/oil passages).

Superior Machinability: Flake graphite acts as a natural lubricant during cutting, reducing tool wear and lowering machining costs by 15% - 20%.

Vibration Damping & Wear Resistance: Flake graphite absorbs operational vibrations, while its structure ensures long - term wear resistance, extending block service life to over 250,000 km.

Cost Efficiency: Mature production processes and abundant raw materials make gray iron blocks 15% - 20% cheaper than alternative materials.

Thermal Conductivity: High thermal conductivity (45 - 55 W/(m·K)) dissipates engine heat to maintain optimal operating temperatures.

(II) Disadvantages

III. Ductile Iron for Engine Blocks

(I) Advantages

(II) Disadvantages

IV. Pig Iron vs. Aluminum: Which Is Better for Engine Blocks?

Aluminum alloys (1/3 the density of cast iron) excel in lightweight EV and fuel - efficient designs but lack hardness/wear resistance (requiring surface treatments) and lose strength at high temperatures.

Conversely, pig iron dominates traditional engines due to its proven durability, cost - effectiveness, and heat resistance—critical for large - displacement/high - torque applications. Selection depends on engine performance, cost, and end - use requirements.

V. Tiegu’s Pig Iron Solutions for Engine Blocks

(I) Product Models & Specifications

(II) Application Cases

VI. Conclusion

Whether you're looking to pig iron for engines, or simply want to have a discussion, feel free to reach out to us!

Phone&WhatsApp: +86 152 5613 5588

Email: zbw@tiegu.net

Fill out our online form for 24 - hour response.

Blog Author Profile

DAWN | Pig Iron & Castings Procurement Advisor 18 years in the foundry trenches give me an edge: I know how pig iron’s chemistry impacts casting quality and can troubleshoot defects like cracks and porosity. With a 1M MT/year pig iron and 60k MT/year casting output from our in-house factory, plus 200+ verified suppliers on our platform, we offer fast price comparisons. Expect a 24-hour inquiry response—my goal? Not just closing deals, but being your go-to partner in the foundry world.

18 years in the foundry trenches give me an edge: I know how pig iron’s chemistry impacts casting quality and can troubleshoot defects like cracks and porosity. With a 1M MT/year pig iron and 60k MT/year casting output from our in-house factory, plus 200+ verified suppliers on our platform, we offer fast price comparisons. Expect a 24-hour inquiry response—my goal? Not just closing deals, but being your go-to partner in the foundry world.

📧(zbw@tiegu.net)

Photos

en

en  fra

fra  de

de  ru

ru  ara

ara  gle

gle  it

it  jp

jp  kor

kor  th

th  zh

zh