The difference between pig iron and cooked iron

2025-05-09 15:12:57 hits:0

Table of Contents

Introduction: The significance of pig iron and wrought iron in industry and daily life, and the meaning of comparing the differences between the two

Basic Concepts of Pig Iron and Wrought Iron

Differences in Chemical Compositions of Pig Iron and Wrought Iron

Comparison of Physical Properties of Pig Iron and Wrought Iron

Differences in Production Processes of Pig Iron and Wrought Iron

Differences in Application Areas of Pig Iron and Wrought Iron

Conclusion: Emphasizing the importance of the two in the industrial field and the value of Tiegu as a pig iron supplier

A Comprehensive Analysis of Pig Iron and Wrought Iron: Properties, Processes, and Applications

In the vast realm of metallic materials, pig iron and wrought iron, as two representatives of iron-carbon alloys, serve as the cornerstone of industrial development, playing an indispensable role in modern industrial production and daily life. Despite the single-character difference in their names, they exhibit significant disparities in chemical composition, physical properties, production processes, and application scenarios. As a professional pig iron supplier, we conduct an in-depth analysis of these two materials to help you better understand the unique value of pig iron.

Basic Concepts of Pig Iron and Wrought Iron

Pig Iron

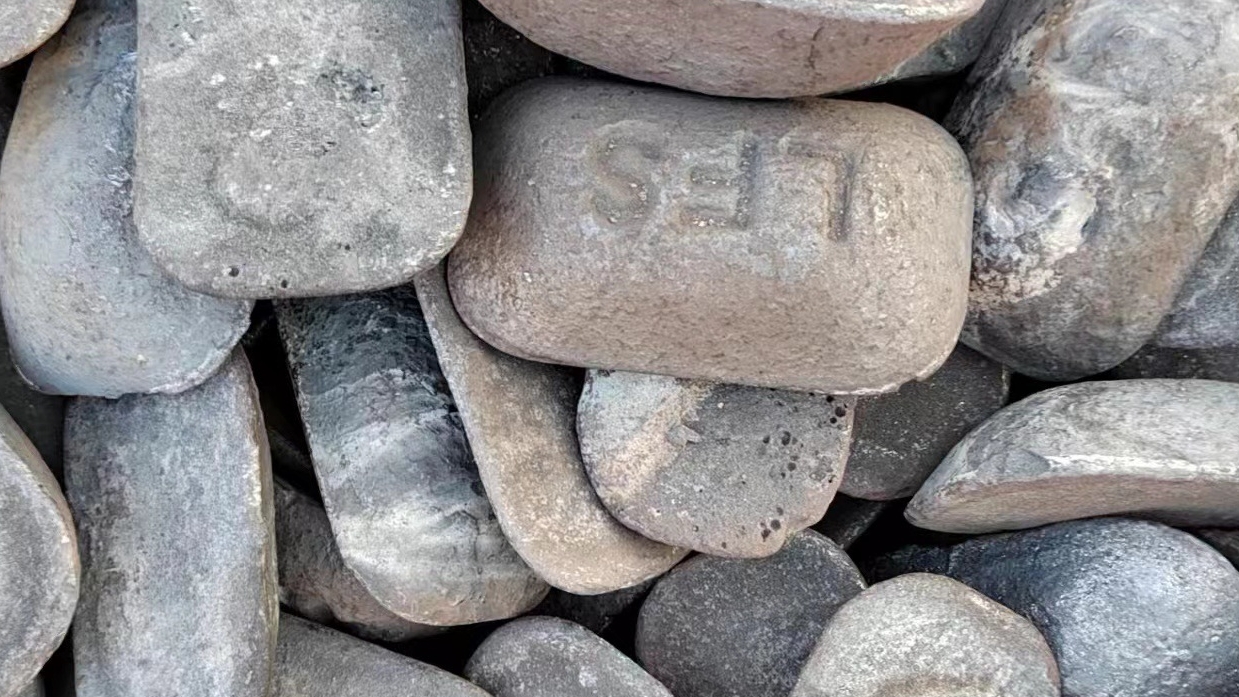

Pig iron, also known as cast iron, is an iron-carbon alloy obtained by reducing iron ore or iron-containing compounds in a blast furnace, with a carbon content exceeding 2%. Pig iron usually appears grayish-black in color, with a rough surface, and contains various impurity elements such as silicon, manganese, phosphorus, and sulfur. In the iron and steel industry, as a key raw material, pig iron occupies a core position in the steelmaking and foundry sectors, serving as an important driving force for industrial production.

Wrought Iron

Wrought iron, also called pure iron, is an iron-carbon alloy obtained through multiple refining and smelting processes of pig iron, with an extremely low carbon content, typically below 0.02%. Wrought iron is soft in texture and has excellent ductility, making it easy to process and forge. It is widely used in many fields such as machinery manufacturing, construction, electricity, and transportation.

Differences in Chemical Compositions of Pig Iron and Wrought Iron

Chemical Composition of Pig Iron

Pig iron mainly consists of iron and carbon, along with impurity elements like silicon, manganese, phosphorus, and sulfur. Among them, the carbon content plays a decisive role in the properties of pig iron. As the carbon content increases, the hardness and brittleness of pig iron significantly increase, while its toughness decreases accordingly. This characteristic enables pig iron with different carbon contents to meet diverse industrial needs, highlighting its importance as a basic raw material in the casting and steelmaking processes.

Chemical Composition of Wrought Iron

The chemical composition of wrought iron is relatively simple, mainly composed of iron and trace amounts of carbon. The extremely low carbon content endows wrought iron with excellent plasticity and toughness, making it easy to be processed and formed. In addition, wrought iron also contains trace amounts of impurity elements such as oxygen and nitrogen, which have a certain impact on its properties.

Comparison of Physical Properties of Pig Iron and Wrought Iron

Physical Properties of Pig Iron

Pig iron has high hardness and brittleness, with poor toughness, and is prone to fracture during tension and compression. Its melting point is relatively low, approximately around 1500°C, and its density is about 7.87 g/cm³. These physical properties determine the unique advantages of pig iron in the foundry field, enabling it to be used for manufacturing products with high requirements for hardness and wear resistance.

Physical Properties of Wrought Iron

Wrought iron has excellent plasticity and toughness, showing good fracture resistance during tension and compression, and is convenient for complex processing and forging. Its melting point is relatively high, about 1538°C. Its density is similar to that of pig iron, but slightly lower due to the lower content of impurity elements.

Differences in Production Processes of Pig Iron and Wrought Iron

Production Process of Pig Iron

The production of pig iron is mainly carried out in a blast furnace. In a high-temperature environment, iron ore and coke undergo a reduction reaction to produce pig iron with a high carbon content. During this process, precise control of parameters such as furnace temperature, furnace pressure, and burden ratio is crucial, directly affecting the quality and output of pig iron. As a professional pig iron supplier, we possess advanced production technology and strict quality control systems to ensure that every batch of pig iron meets high-standard quality requirements.

Production Process of Wrought Iron

The production of wrought iron requires a series of processes such as steelmaking and forging. First, pig iron is put into a steelmaking furnace, and the carbon content is reduced and impurity elements are removed through oxidation and reduction reactions. Then, the molten steel obtained is poured into a mold to cool and solidify into steel ingots. Finally, the steel ingots are processed into the required shapes and sizes through forging and other processes. Throughout the production process, strict control of parameters such as smelting temperature, time, and atmosphere is the key to ensuring the quality and performance of wrought iron.

Differences in Application Areas of Pig Iron and Wrought Iron

Application Areas of Pig Iron

In the foundry industry, pig iron, with its high hardness and good casting properties, is widely used to manufacture various castings such as mechanical parts, pipes, and valves. Meanwhile, pig iron is also an important raw material for the production of ferroalloys and some chemical products. The pig iron supplied by our company, with its stable quality and excellent performance, has won the trust of numerous customers, providing solid support for the development of the foundry and related industries.

Application Areas of Wrought Iron

Thanks to its excellent plasticity and toughness, wrought iron is often used to manufacture various mechanical parts in the machinery manufacturing industry. In the construction field, it is used to produce construction materials such as steel bars and steel pipes. In the electricity industry, it is applied to manufacture electrical equipment such as generators and transformers. In the transportation industry, it is used to make components of vehicles, trains, ships, and other means of transportation.

The significant differences between pig iron and wrought iron in chemical composition, physical properties, production processes, and application areas enable them to play irreplaceable roles in the industrial field. As a professional pig iron supplier, we are always committed to providing high-quality pig iron products for the pig iron casting and steelmaking industries. With advanced production technology and a complete service system, we meet the diverse needs of customers and help industrial production reach new heights.

For more detailed information about our pig iron products, please visit [https://www.tieguexport.com/index.php?s=custom&c=ad].

en

en  fra

fra  de

de  ru

ru  ara

ara  gle

gle  it

it  jp

jp  kor

kor  th

th  zh

zh