A Comprehensive Analysis of Pumps: From Basic Principles to the Selection of High-Quality Supplier

2025-04-23 11:26:11 hits:0

In industrial production and daily life, pumps are crucial devices for fluid transportation, playing a core role in numerous fields such as the chemical industry and water supply. Let's take an in-depth look at the relevant knowledge about pumps.

What is a Pump?

A pump is a mechanical device that converts mechanical energy into fluid energy, thus achieving fluid transportation. It exerts pressure on the fluid to overcome pipeline resistance and lift the fluid to a certain height. According to the relevant content on Chem17.com (https://www.chem17.com/tech_news/detail/1883046.html), a pump uses the pressure effect to first create a negative pressure to suck in the fluid and then generates pressure through the suction and discharge processes to transport the fluid.

Classification Standards of Pumps

There are various classification standards for pumps. Common ones include working principles, structural forms, transported media, and operating conditions. Classification according to working principles is the most widely used method, which can reflect the essential characteristics of pumps. Classification by structural forms helps in understanding the construction of pumps. Classification by transported media makes it convenient to select appropriate pump types, and classification by operating conditions can meet the requirements of special environments. These classification methods are elaborated in detail in professional literatures and mechanical engineering textbooks.

Types of Pumps

Positive Displacement Pumps

Positive displacement pumps transport fluids by periodically changing the volume of the pump chamber. Their flow rate is stable and not affected by the system pressure. For example, gear pumps and screw pumps are often used for precise metering and the transportation of high-viscosity fluids, such as lubricating oil and paint. The relevant materials on Huanbao.bjx.com.cn (https://huanbao.bjx.com.cn/news/20210421/1168659.shtml) provide detailed descriptions of the working processes of some types of positive displacement pumps.

Rotary Pumps

Rotary pumps are a special form of positive displacement pumps, which achieve fluid transportation by the rotation of the rotor. They are compact in structure, operate stably, and produce low noise. They are suitable for transporting clean liquids and are widely used in the food and pharmaceutical industries.

Reciprocating Pumps

Reciprocating pumps transport fluids through the reciprocating motion of pistons or plungers in the pump cylinder. Their flow rate is uneven, but they have a high head. They are often used in high-pressure and small-flow situations, such as metering pumps in the petrochemical industry and oilfield water injection.

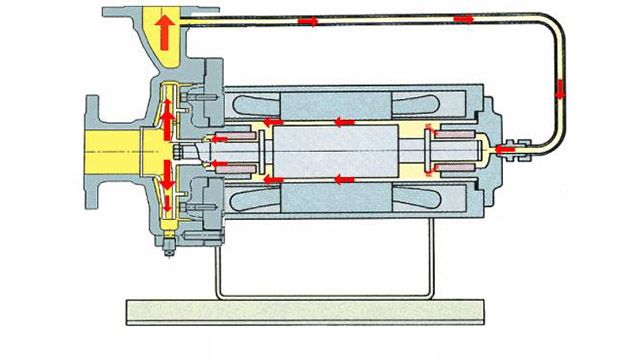

Dynamic Pumps

Dynamic pumps, also known as vane pumps, transport fluids by the centrifugal force or thrust generated by the rotation of the impeller. Centrifugal pumps are typical representatives. They have a large flow rate, simple structure, and convenient operation, and are widely used in fields such as water supply and drainage and agricultural irrigation. The relevant content on Huanbao.bjx.com.cn (https://huanbao.bjx.com.cn/news/20210421/1168659.shtml) elaborates in detail on the working principle of centrifugal pumps.

Special-Purpose Pumps

Special-purpose pumps are designed for special working conditions and media. For example, magnetic pumps are used for transporting hazardous media, canned pumps can avoid leakage, and metering pumps can precisely control the flow rate. They are often used in chemical batching, sewage treatment, and other applications.

The Significance of Pump Housing Castings to the Quality of Pumps

Pump housing castings are key components of pumps and affect the quality and performance of pumps. They need to withstand internal and external pressures and have sufficient strength and stiffness to prevent deformation and breakage. A good casting process can ensure dimensional accuracy and surface quality, reduce friction and leakage, and improve the efficiency and reliability of pumps. Corrosion resistance is also crucial, as it can extend the service life of pumps and reduce maintenance costs.

How to Find a Pump Casting Supplier

Selecting a high-quality pump casting supplier requires comprehensive consideration of various factors. In terms of production capacity, it includes the advanced nature of casting equipment, production scale, and production capacity. A perfect quality control system is essential, strictly controlling the inspection process from raw materials to finished products. Strong technical research and development capabilities are also important, being able to provide customized solutions. At the same time, after-sales service, delivery time, and price should not be overlooked. Suppliers can be screened through on-site inspections, customer evaluations, and industry reputation.

The Advantages of Tiegu castings

Self-Sufficient Supply of Raw Materials (Pig Iron)

Tiegu has a self-sufficient supply of pig iron, which can ensure the stable supply of raw materials and avoid the impact of market fluctuations. At the same time, it strictly controls the quality of pig iron, providing a guarantee for the production of high-quality pump housing castings.

Advantages of Other Raw Material Supply Chains

Tiegu cooperates with high-quality suppliers to obtain high-quality auxiliary materials. Its efficient supply chain management system reduces costs and improves production efficiency, making its products more cost-effective.

Technical Strength

Tiegu has strong technical strength, equipped with advanced casting equipment and testing instruments. It adopts high-precision mold manufacturing and advanced processes to ensure that product quality is at a leading level in the industry. The technical team can also provide one-stop solutions, creating greater value for customers.

Conclusion

Pumps are of great significance in various fields. Understanding the knowledge of pumps helps in selecting appropriate pump types and suppliers. With its advantages in raw materials, the supply chain, and technology, Tiegu can provide high-quality products and services and is a trustworthy partner. If you have requirements for pump castings, you may consider cooperating with Tiegu.

en

en  fra

fra  de

de  ru

ru  ara

ara  gle

gle  it

it  jp

jp  kor

kor  th

th  zh

zh